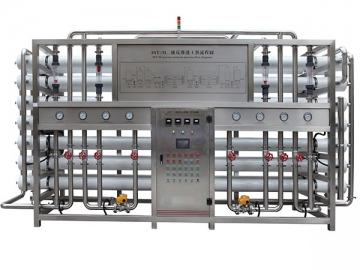

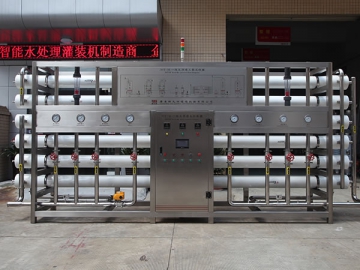

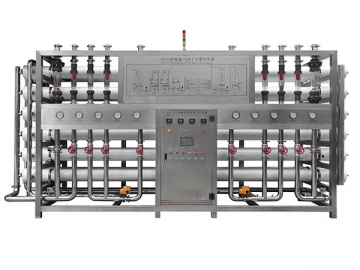

Reverse Osmosis System

The reverse osmosis element consists of a spirally wound machine separated by a spacer. The untreated water is led across the membrane from the side. Permeated water then passes across the spacer to the permeate collection pipe in the middle of the spirally wound module. After flowing through the reverse osmosis element, the concentrate is led to the nearest element or led off. By using consecutive arranging of several spirally wound elements in a pressure pipe, a bank configuration is set up, allowing for a graduated treatment of the concentrate.

The banked configuration is also utilized in the cleaning process. By using a selective disabling of a portion of the reverse osmosis system, the membrane unit can be rinsed with the permeate formed through the system operation process.

Customized designs and solutions are available based on different raw water sources, and we pay strict attention to each individual process to ensure the final purified water is both safe and healthy for consumption.

Water Saving Technology

- patented concentrated water recycling

- Uses technology and design optimization to achieve water conservation

Energy Saving and Reduces Consumption

- Uses frequency conversion technology

- Technology and design optimization reduces consumption

Online Monitoring

- Remote human to machine interface monitoring

- Each stage and its working status can be monitored online

Aseptic Piping

- German standard automatic welding technology is used for no dead angles

Benefits of EcoPura's Reverse Osmosis System

1. Efficient structure with individual banks: In the event of a change in the conductivity of the permeate, users can also test the individual reverse osmosis elements in the line and check for malfunctions. Spiral elements found to be faulty can then be changed individually without replacing the entire system.

2. Step by Step CIP Sequences: During the CIP process, the CIP tank can be filled with the permeate. By doing so, all chemicals are rinsed out of the reverse osmosis modules connected bank to bank. The individual banks are then individually cleaned one right after the other.

3. Rinsing with Permeate: To prevent scaling and biofouling, the reverse osmosis system is rinsed with the permeate before a long period of non-use, until the conductivity values in the concentrate and in the permeate are equal.

4. Modular, Long Term Structure: Due to the specific modular design of the system, and its high manufacturing quality, the water treatment system has a long service life. The design's large total membrane surface also results in a slight load and high service life for the individual membrane elements.

5. Economic Energy Use: The regulation of the permeate capacity is set according to admission pressure and temperature of the untreated water, leading to a low energy consumption.