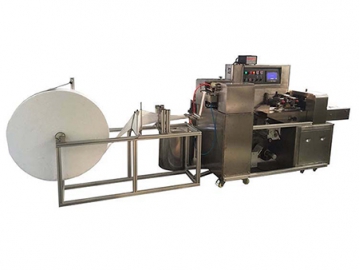

Sachet Packaging Machine

Basic Features of the Sachet Filling Packing Machine:

- Automatic film feeding

- Sachet forming

- Vertical & horizontal sealing

- Quantitative filling

- Date coding

- Counting

Structure of the Sachet Packing Machine

- The frame and other components that come into contact with the liquid are S.S304. The packing machine is equipped with a water pump for water filling, as well as a motor and speed reducer control unit for the speed control of the film distribution system.

- The film dispensing unit is comprised of the film setting system, a film guiding SS304 steel post, a vertical thermal heating sealing rubber and copper system, and a horizontal thermal sealing and cutting system. The film is formed according to the film setting process, in order to pre- form bags for filling water.

- The sealing system is composed of the film inlet guiding post, a wheel, thermal heating modular, thermal heating tube, temperature controller and a pressure adjusting spring valve.

- The film output system is made from a SS304 sliding rail plate.

- The electrical control system is composed of a control panel wiring, and the AC contactor system.

- Automated date coder and counting unit.

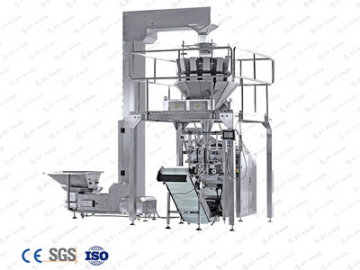

No matter what your raw water source, whether it be tap water or borehole water, users can use the reverse osmosis purification system to get clean, healthy and purified drinking water to store in an SS304 water storage tank, or connect piping to an automatic sachet water packing machine, in order to ultimately produce sachet water with your own company logo on the package.

EcoPura's 1000L/H RO water treatment system is ideal for sachet water machines with a capacity of 2000 sachets per hour at a maximum size of 500ml. Other popular sizes for the water sachet include 250ml, 300ml, 330ml, and 450ml.