i-Sleeve Single Head Shrink Sleeve Labeling Machine

Automatic shrink sleeve label applicator for speeds up to 150BPM

i-Sleeve is a single head sleeve labeling machine under our product line, with a standard speed of 150 bottles per minute (BPM). It is widely used in various packaging industries, including beverage and dairy packaging, and is capable of applying sleeves in multiple packaging formats such as bottle necks, full bodies, and partial bodies. i-Sleeve is equipped with an ultra-thin knife and features a unique conveyor belt system, making it easy to adjust and disassemble while facilitating seamless integration with packaging production lines.

- Maximum Speed: 150 bottles per minute (BPM)

- Sleeve Labeling Container Outer Diameter: Ø25mm to Ø125mm (based on customer-provided bottle specifications)

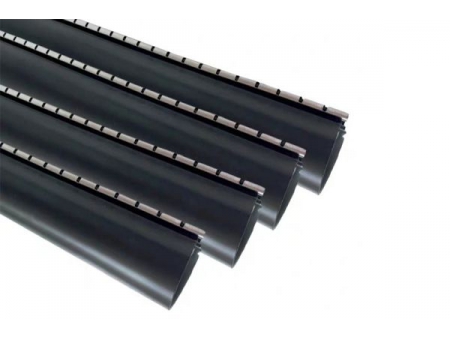

- Film Material: PVC / PET / OPS

- Film Thickness: PVC: 0.035mm to 0.08mm, PET: 0.04mm to 0.06mm, OPS: 0.04mm to 0.06mm

- Machine Dimensions: 1230mm * 952 mm * 2163mm (L * W * H) (The company reserves the right to modify the machine's external dimensions for equipment optimization)

- Voltage: 3-phase; 220V

- i-Sleeve single head shrink sleeve labeling machine is designed with a separated body and conveyor belt, allowing it to be used in conjunction with any packaging production line for continuous packaging and sleeve operations.

- Our sleeve labeling machine features a protective cover with a user-friendly control interface where all parameters can be easily set, enabling effortless control of the labeling equipment.

- The unique knife seat design eliminates the need to change seats within the specified range; if replacement is necessary, it can be completed quickly within minutes.

- The sleeve labeling design helps save production costs.

- The user-friendly design enables easy adjustment of the entire machine's transmission mechanism when producing labels of various sizes.

- The inner diameter of the paper tube can be adjusted without stages within the range of 5" to 10".

- Our sleeve labeling machine utilizes a PLC (Programmable Logic Controller) conveyor system to enhance the accuracy and speed of sleeve labeling.

- The ultra-thin knife design, along with fixed belt tension, simplifies adjustment and disassembly.

- The manual lift and worm gear design allows for easy adjustment, with a larger adjustment range compared to traditional machines.

- The unique power and conveyor structure boasts a simple design.

- The entire machine uses only three timing belts, making disassembly and maintenance straightforward.

- Neck Tamper Evident Banding Suitable for sealing various bottle and can necks, preventing product tampering, opening, or other object insertion before sale, ensuring the original packaging and product quality are preserved.

- Full Body Over-The-Cap Sleeve Labeling Labels cover the entire bottle, including the neck, body, and bottom. Commonly used for products like sauces and condiments.

- Full Body Shrink Sleeve Labeling Labels cover from the lower edge of the bottle neck to the bottom of the bottle. Often used for products like juices and coffee.

- Partial Body Shrink Sleeve Labeling Labels are positioned in the center of the bottle body, a common packaging type used for various bottles and canned products.

- Full Body & Underlap Sleeve Labeling Specifically designed for products requiring packaging down to the bottom, showcasing product design aesthetics and offering a more visually appealing appearance.

Our shrink sleeve labeling machine finds extensive use in various packaging industries, including beverage packaging, dairy packaging, pharmaceutical packaging, personal care packaging, and more. It is suitable for different sizes and shapes of bottles or containers, including square, curved, cup-shaped, and unique types of packaging bottles.