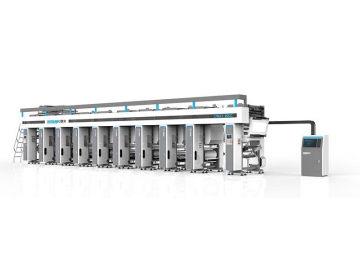

Industrial Rotogravure Press, DNAY800D/1100D Film Printing

Request a Quote

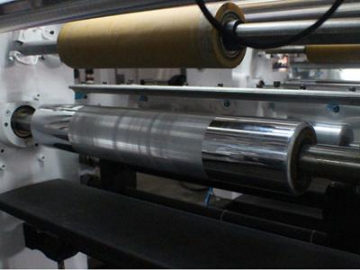

AY800/1100D industrial rotogravure press has no substructure to connect all printing units. It can reach speed up to 150m/min and operate stably.

This industrial rotogravure press is driven by three servo motors and consoled through PLC controller, and is capable of automatically connecting successive web rolls.

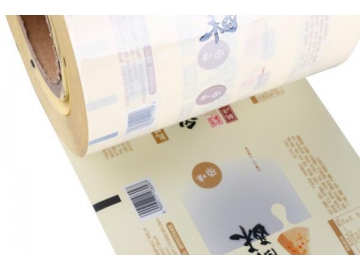

Adaptive material of print surfaceBOPP,CPP,PET,PC,PVC and composite film or paper, etc. of the same texture.

| Model | DNAY800D | DNAY1100D |

| Printing width | 800mm | 1100mm |

| Material width | 830mm | 1130mm |

| Printing cylinder diameter | φ100-350mm | φ100-350mm |

| Printing speed | 150m/min | 150m/min |

| Unwind diameter | 600mm | 600mm |

| Rewind diameter | 600mm | 600mm |

| Register accuracy | 0.1mm | 0.1mm |

| Total power | 140KW | 150KW |

| Weight | 17000KG | 18000KG |

| Dimension | 12000×3800×2800mm | 12000×4100×2800mm |

1. Three servo motors respectively drive main motor, unwinding system and rewinding system, ensuring the sensitiveness and stability of operation.

1. Three servo motors respectively drive main motor, unwinding system and rewinding system, ensuring the sensitiveness and stability of operation.  2. Doctor blade controlled by dual-cylinder can scrape the cylinder clearer.

2. Doctor blade controlled by dual-cylinder can scrape the cylinder clearer.  3. Impression system driven by dual-cylinder can precisely control the printing pressure, fully present the expectation of printing.

3. Impression system driven by dual-cylinder can precisely control the printing pressure, fully present the expectation of printing.  4. The video surveillance system controlled by computer will inform the workers when the patterns on printed product deviates. This can considerably reduce defective index.

4. The video surveillance system controlled by computer will inform the workers when the patterns on printed product deviates. This can considerably reduce defective index.  5. Isolated drying system and air circulation system dry the printings with hot air produced by the machine itself. This promotes the efficiency of the printing as well as reduce energy cost.

5. Isolated drying system and air circulation system dry the printings with hot air produced by the machine itself. This promotes the efficiency of the printing as well as reduce energy cost.  6. The pneumatic dryer can switch on and off automatically, which simplifies manual work.

6. The pneumatic dryer can switch on and off automatically, which simplifies manual work.  7. Reverse roller can be installed on this industrial rotogravure press to print double sides directly through printing reversely.

7. Reverse roller can be installed on this industrial rotogravure press to print double sides directly through printing reversely.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos