Tube Capper, tube capping machine

Description of product

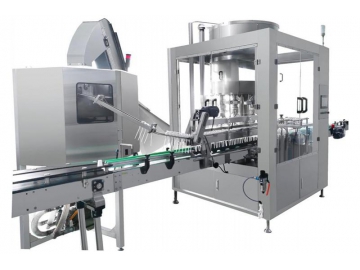

The NMG01 capping machine is mainly used for automatic upper cover work in the aluminum tube production process. The NMG01 capping machine has a wide range of application and can cover different types of plastic covers.

The printed aluminum tubes enter the covering machine after drying in the oven, and the cap is rotated to the tube mouth through the rotation of the covering manipulator. The device can automatically plug the central mandrel for aluminum tubes that need to screw the cap or clean head on the conveyor boat. The cylinder is equipped with a cleaning head according to the frequency, and screw cap on the aluminum tube of rotating central mandrel by means of clamping the cap cover with a cylinder driving clip cap wrench. The machine can screw the cap in double work position, tighten the cap, release the aluminum pipe and other operations all at once. The aluminum tube is covered with a central mandrel, cleaning head or cap. The scraper scrapes the aluminum tube with the tight cap off the central mandrel and transports it to the next procedure through the pipe components.

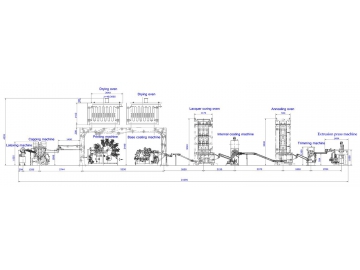

The machine can be used alone or with other aluminum tube manufacturing equipment to form a complete automatic machine line.

Technical parameter- Suitable diameter of tube: 16-25mm25-35mm

- Maximum suitable length of tube: 200mm

- Production rate: 90-120 tubes/minute

- Total power: 6.6KW

- Size of shape: 2250×2200×2140mm

- Total weight: 3.2 tons

- Inlet pressure: 0.6Mpa

- Double work screw cap action adopts a double cylinder structure. The cylinder drives the clippers to open and close the cap.

- The equipment can automatically detect the phenomenon that the mandrel has no aluminum tube by a promixity switch. When there is no tube, the machine does not cover the cleaning head or cap.

- The device converts the motion of continuous rotation into the intermittent power between the central mandrel and the drum through the fusion mechanism.

Transmission chain

Transmission chain Electric machinery

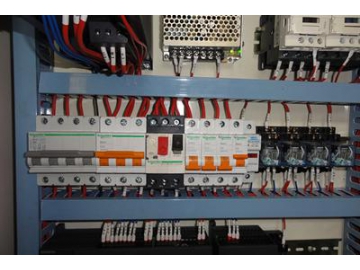

Electric machinery Electric box

Electric box Electro-magnetic valve

Electro-magnetic valve Cylinder

Cylinder Control electric box

Control electric box Control panel

Control panel Pneumatic valve

Pneumatic valve