Metal Cased Polyurethane Seals

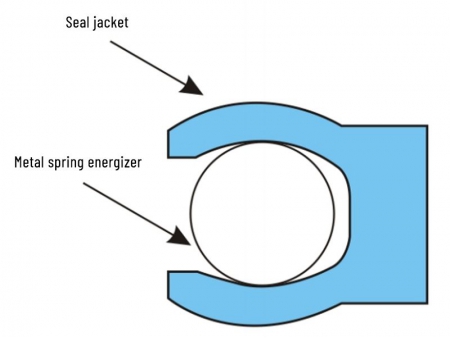

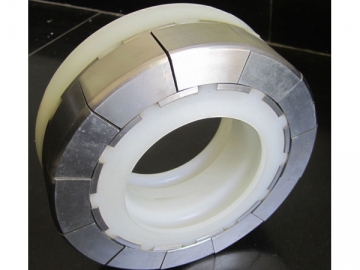

The metal cased polyurethane seal differs from the high pressure seal in that it comes with a metal case around its outer diameter. Except that difference, this hydraulic seal has almost all the same features as its cousin, including the metal reinforcements around the inner ring and the polyurethane sealing element.

Because the metal cased PU seal is to be fitted inside the steel pipe during a hydrostatic pressure test, the elastomeric body will expand outwards when being pressurized. This expansion pushes the metal case closely against the internal wall of the pipe, thereby forming a tight seal. The pressure-energized sealis cheap to manufacturer, a major advantage over the high pressure seal line. It is, however, equally suitable for sealing casing pipes, production tubing, and natural gas pipes during hydrostatic testing.

We currently offer more than 40 models of such static seals for customers to choose from, which are typically used to seal 97mm~762mm diameter steel pipes.

Applications

Steel casing pipes, oil production tubing, and other steel pipes certified to API 5CT/ISO11960:2011, GB/T9711.1-2011, and GB/T9711.2-2011 standards in oil and natural gas industry; GB8163-2008 seamless steel pipes; GB/T3092-2008 welded steel pipes

Working pressure ≤60 MPa

Working temperature: -20°C~ 80°C

Operating media: water, hydraulic oil, emulsified fluid

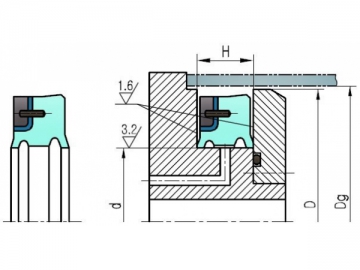

Metal Cased Polyurethane Seal Schematic Diagram

| No. | Type | Pipe diameter range | Groove Dimension | Order No. | ||

| Groove diameter d | Metal case diameter D | Groove width H 0.5 | ||||

| 1 | NM87 | 97-106 | 41 | 92 | 47 | |

| 2 | NM91 | 101-111 | 41 | 96 | 47 | |

| 3 | NM128 | 138-145 | 40 | 134 | 58.5 | |

| 4 | NM136 | 146-156 | 70 | 141 | 47 | |

| 5 | NM157 | 167-177 | 94 | 162 | 52 | |

| 6 | NM163 | 173-183 | 94 | 168 | 52 | |

| 7 | NM178 | 188-198 | 90 | 184 | 58.5 | |

| 8 | NM183 | 195-205 | 120 | 190 | 52 | |

| 9 | NM193 | 205-215 | 120 | 200 | 52 | |

| 10 | NM198 | 210-220 | 140.5 | 205 | 38 | |

| 11 | NM213 | 225-235 | 136 | 220 | 52 | |

| 12 | NM217 | 229-239 | 136 | 224 | 52 | |

| 13 | NM243 | 255-265 | 154 | 250 | 52 | |

| 14 | NM270 | 282-292 | 180 | 227 | 52 | |

| 15 | NM280 | 292-302 | 190 | 287 | 52 | |

| 16 | NM310 | 322-332 | 227 | 317 | 52 | |

| 17 | NM318 | 330-340 | 230 | 325 | 52 | |

| 18 | NM352 | 364-376 | 235 | 359 | 52 | |

| 19 | NM390 | 402-415 | 257 | 397 | 65 | |

| 20 | NM418 | 431-444 | 297 | 425 | 65 | |

| 21 | NM430 | 444-457 | 298 | 438 | 65 | |

| 22 | NM435 | 449-459 | 346 | 443 | 52 | |

| 23 | NM444 | 458-472 | 310 | 452 | 65 | |

| 24 | NM461 | 476-490 | 328 | 470 | 65 | |

| 25 | NM490A | 504-518 | 295 | 498 | 85 | |

| 26 | NM490 | 504-518 | 358 | 498 | 65 | |

| 27 | NM516 | 531-545 | 402 | 525 | 47 | |

| 28 | NM518 | 532-542 | 378 | 526 | 65 | |

| 29 | NM538 | 552-566 | 406 | 546 | 65 | |

| 30 | NM540 | 554-570 | 380 | 548 | 65 | |

| 31 | NM560 | 574-588 | 427 | 568 | 65 | |

| 32 | NM568 | 583-595 | 448 | 576 | 52 | |

| 33 | NM588 | 603-617 | 457 | 596 | 65 | |

| 34 | NM620 | 637-652 | 457 | 630 | 65 | |

| 35 | NM640 | 657-672 | 484 | 650 | 65 | |

| 36 | NM667 | 684-699 | 484 | 677 | 65 | |

| 37 | NM687 | 704-719 | 484 | 697 | 79 | |

| 38 | NM693 | 710-725 | 548 | 703 | 65 | |

| 39 | NM695 | 712-727 | 510 | 705 | 65 | |

| 40 | NM705 | 722-737 | 510 | 715 | 65 | |

| 41 | NM730 | 747-762 | 540 | 740 | 65 | |