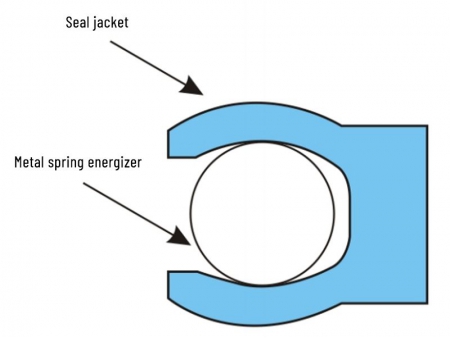

Spring Energized Seals

Metal spring energizer

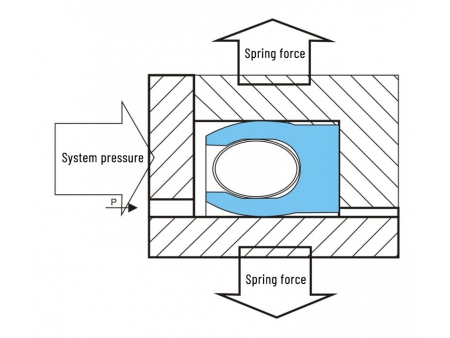

Spring force

System pressure

Spring-energized seal typically consists of two basic components: the seal jacket and a corrosion resistant metal ring. When the seal is seated in the gland, the spring is under compression and it responds with constant force, pushing out the sealing lips and creating a gas tight seal against the sealing surface. The spring also provides resiliency to compensate for seal wear, gland misalignment or eccentricity. While spring force offers adequate force for sealing at low pressure, at high pressure the system pressure augments the spring force to provide tighter sealing.

- Excellent dynamic and static sealing

- Low friction: low coefficient of friction offers good wear resistance

- High surface speed capability: up to 15 m/s

- Wide temperature range: from -196 to 300 ℃

- Almost universal chemical compatibility

- Outstanding resistance to gap extrusion

The seal jacket of spring-energized seals is made from PTFE and other high-performance polymers. Spring-energized seals with a PTFE jacket are capable of operating over a wide temperature range from -196℃ to 300℃. They are virtually unlimited chemically inert, except for molten alkali metals, fluorine gas at high temperatures and Chlorine Trifluoride (CIF3). Spring force can meet the extremely demanding low friction requirements in dynamic applications, as well as the high load requirements needed for low-temperature sealing.