Die-Formed Sucker Production Line

Request a Quote

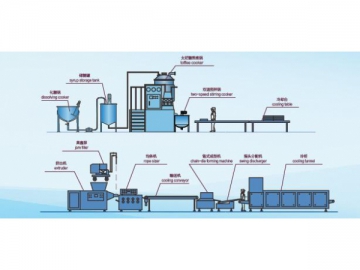

The die-formed sucker production line produces suckers in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different sucker shapes and features a maximum capacity of 400kg.hour. TG Machine’s die-formed sucker production line is equipped with an electric heating cooker to ensure an even PLC controlled heating time and temperature, ensuring the sucker is transparent and features a good taste. This advanced sucker production equipment effectively reduces material waste. Backed by extensive experience, not only do we offer customized die-formed sucker production lines, but we also offer the matched molds.

- Sugar dissolving cooker

- Liquid glucose storage

- Continuous vacuum cooker

- Cold table

- Batch roller

- Rope sizer

- Die forming machine

- Shaking distribution conveyor

- Refrigerated cooler

- The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

- The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

- Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

- By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.

- It is easy to operate and maintain.

- The production line can be customized to fit your site conditions.

- Standard

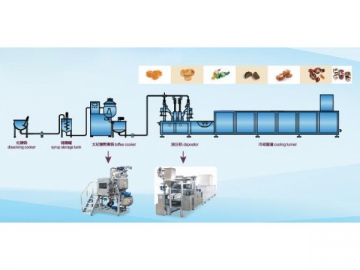

- Continuous vacuum cooker

It features an automatic temperature control and high output performance that saves time with its short cooking process. Syrup manufactured using this cooker features an excellent transparency.

It features an automatic temperature control and high output performance that saves time with its short cooking process. Syrup manufactured using this cooker features an excellent transparency. - Forming machine

The forming machine is designed to manufacture hard candy in different specifications. It can be modified to produce hard candy in a variety of shapes according to your needs.

The forming machine is designed to manufacture hard candy in different specifications. It can be modified to produce hard candy in a variety of shapes according to your needs.

- Continuous vacuum cooker

- Optional

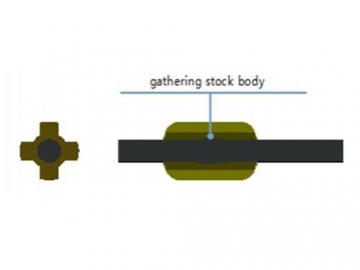

- Extruder

The extruder ensures the production line is capable of manufacturing filled hard candy.

The extruder ensures the production line is capable of manufacturing filled hard candy. - Kneading and cooling machine

This machine fully mixes syrups and flavors to ensure an excellent candy taste.

This machine fully mixes syrups and flavors to ensure an excellent candy taste.

- Extruder

Production Line Recommendations

- YT200L Die-formed hard candy production line

This production line is cost-effective and suitable for small-scale candy plants. Its capacity is 100-200kg/h.

This production line is cost-effective and suitable for small-scale candy plants. Its capacity is 100-200kg/h. - YT400L Automatic die-formed hard candy production line

This automatic production line is equipped with a vacuum cooker to effectively reduce syrup temperature, ensuring it is more transparent and increases the hard candy quality.

This automatic production line is equipped with a vacuum cooker to effectively reduce syrup temperature, ensuring it is more transparent and increases the hard candy quality.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos