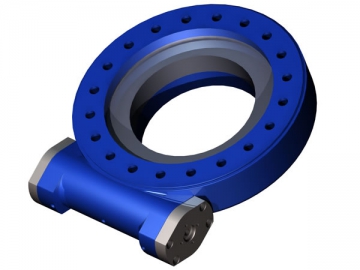

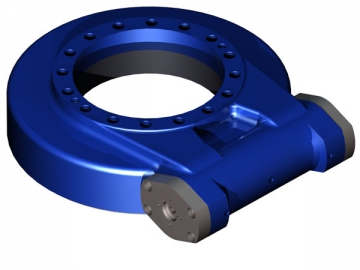

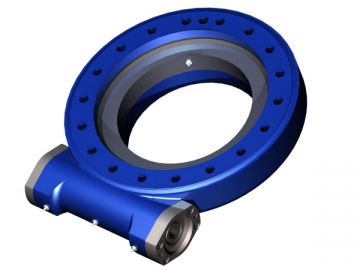

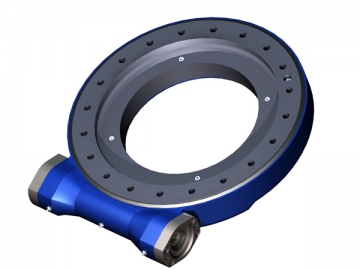

ZE Series Horizontally Mounted Slewing Drive

Description

The ZE series horizontally mounted slewing drive provides an ideal solution for precise rotation. Owing to a special worm design, the worm drive is able to compensate transmission clearance in real time, thus realizing zero clearance transmission.

Our zero backlash gearbox is characterized by precise repeat positioning and high transmission efficiency. It is mainly used in the occasions where small torque and high transmission precision are required, such as the rotation of medical equipment or automated robot.

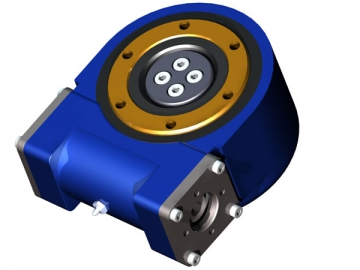

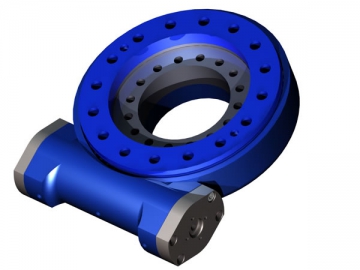

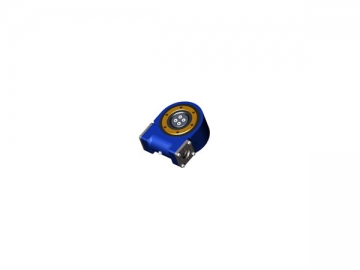

Features

1. With the gear meshing of zero backlash, our slewing drive enjoys higher transmission precision in comparison with the precise type product.

2. The exposed metal surfaces of our worm gearing are all processed by a special paint, so the slew drive has stronger corrosion resistance.

3. Our company is one of few manufacturers that are able to offer zero backlash slewing drive in the world. The zero backlash positioner is often used in the robotic arms and solar concentrators.

Supply Capacity

We can meet your special requirements on gear reducer.

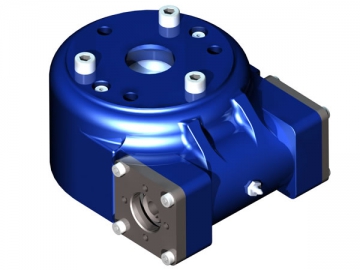

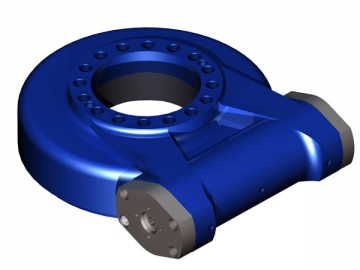

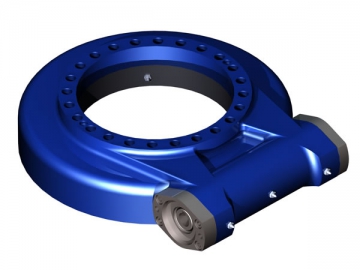

Application

The ZE series zero backlash slewing drive is widely used in the machinery and solar energy fields.

a. Horizontal and pitch transmission of photovoltaic and solar thermal power generation tracking systems

b. Rotating platform

c. Rotation of medical equipment joints

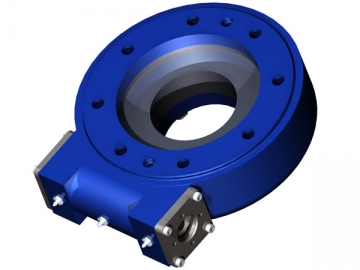

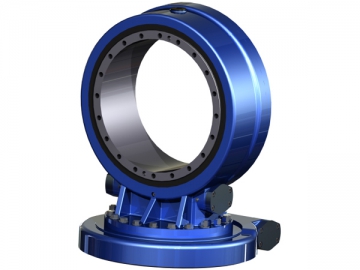

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| | 240 Nm | 1100 Nm | 2000 Nm | 30 kN | 16.6 kN | 9.6 kN | 8.4 kN | 62:1 | 0° | 12kg |

| 177 lbf•ft | 811 lbf•ft | 1475 lbf•ft | 6744 lbf | 3732 lbf | 2158 lbf | 1888 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| 600 Nm | 13500 Nm | 10400 Nm | 133 kN | 53 kN | 32 kN | 28 kN | 73:1 | 0° | 21kg | |

| 443 lbf•ft | 9957 lbf•ft | 7671 lbf•ft | 29900 lbf | 11915 lbf | 7194 lbf | 6295 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| 3.9 kN•m | 33.9 kN•m | 38.7 kN•m | 338 kN | 135 kN | 81 kN | 71 kN | 61:1 | 0° | 49kg | |

| 2876 lbf•ft | 25×10^3 lbf•ft | 29×10^3 lbf•ft | 76×10^3 lbf | 30×10^3 lbf | 18×10^3 lbf | 16×10^3 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| 4.5 kN•m | 54.3 kN•m | 43 kN•m | 475 kN | 190 kN | 114 kN | 100 kN | 78:1 | 0° | 61kg | |

| 3319 lbf•ft | 40×10^3 lbf•ft | 32×10^3 lbf•ft | 107×10^3 lbf | 43×10^3 lbf | 26×10^3 lbf | 23×10^3 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| 4.8 kN•m | 67.8 kN•m | 48 kN•m | 555 kN | 222 kN | 133 kN | 117 kN | 85 : 1 | 0° | 64kg | |

| 3500 lbf•ft | 50×10^3 lbf•ft | 35×10^3 lbf•ft | 125×10^3 lbf | 50×10^3 lbf | 30×10^3 lbf | 26×10^3 lbf |