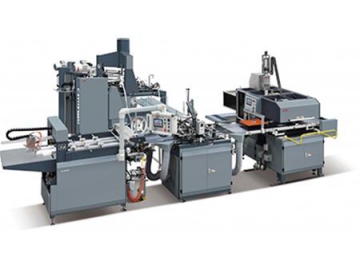

Automatic Rigid Box Making Machine, LY-HB1200CN

Complete Box Line for Manufacturing Rigid Box

The LY-HB1200CN automatic rigid box making machine is specifically designed to produce high-quality small boxes quickly and efficiently. Whether it’s phone boxes, jewelry boxes, cosmetic boxes, or watch boxes, this paper box machine can handle a wide range of two-piece rigid boxes with ease.

Jewelry Box

Jewelry Box Book-style Box

Book-style Box Two-piece Box

Two-piece Box- Hinged Lid Shoulder Box

Irregular Shaped Box

Irregular Shaped Box

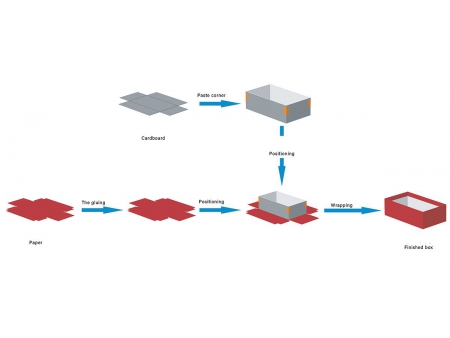

Equipped with advanced features such as servo control and image positioning, the rigid box making machine can seamlessly perform tasks such as paper feeding, gluing, cardboard feeding, corner pasting, positioning, grasping the box, edge wrapping, flap folding and box forming, all without any human intervention. To ensure not just functionality but also safety and aesthetics, the entire box machine has undergone a complete redesign to make it more visually appealing and safer to use.

Features- The feeder, glue applicator, and belt conveyor are equipped with servo drives from well-known brands like Panasonic, allowing for variable speed, high precision, easy adjustment, and time savings.

- The positioning for the corner pasting is equipped with an image positioning system and robotic arm to improve precision and efficiency, with the error range of ±0.05mm, as well as faster positioning and debugging speeds.

- The rigid box wrapping machine uses THK linear guides and virtual electronic cam drive, which is more stable, wear-resistant, and smoother in motion, with a larger size range for folding depth and flap length dimensions.

- The automatic box making machine is suitable for making high-quality paper boxes by interlocking or overlapping the short flaps of the box.

- A new adhesive application method is available for both white glue and hot melt adhesive.

- The rigid box making machine is capable of making slotted paper products and completing edge wrapping and flap folding in one go.

| Paper Size | L | 120 mm-880 mm |

| W | 95 mm-600 mm | |

| Paper Thickness | 80-300 g/㎡ | |

| Pile Height | 850 mm | |

| Cardboard Thickness | 1-3 mm | |

| Finished Box Size | L | 55 mm-380 mm |

| W | 55 mm-280 mm | |

| H | 15 mm-120 mm | |

| Positioning Accuracy | ±0.05 mm | |

| Manufacturing Speed | 20-30 pcs/min | |

| Glue Container Volume | 50 KG | |

| Air Pressure | 175 L/min | |

| Weight | 7200 KG | |

| Overall Size (L *W* H) | 8500* 3400*3500 mm | |

- All computer-based settings

- Troubleshooting

- Automatic feeding of covering papers and cardboards

- 24-hour control for preheating glue

- 999 built-in formulas in the box making machine

- Separate HMI (human machine interface) of box heat-sealing

- INOVANCE servo control system

- Image positioning system and robotic picking & placing (with an error of ±0.05 mm)

- Automatic box lifting and retrieval

- Automatic system of adhesive viscosity control (optional)

- Convertibility to be equipped with cardboard splicing machine (optional)

-

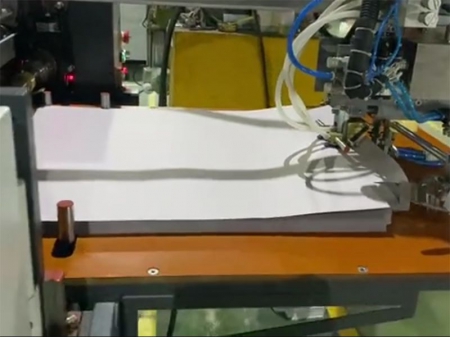

Paper Feeder

Paper Feeder- Full servo controlled dual feeders ensure feeding stability.

- Front-suctioning and rear-blowing feeders avoid double-sheet feeding.

- 620mm wide glue roller allows feeding single or double-sided paper simultaneously.

-

Paper Pallet

Paper Pallet- Less loading pauses as maximum pile height mounting up to 850 mm.

-

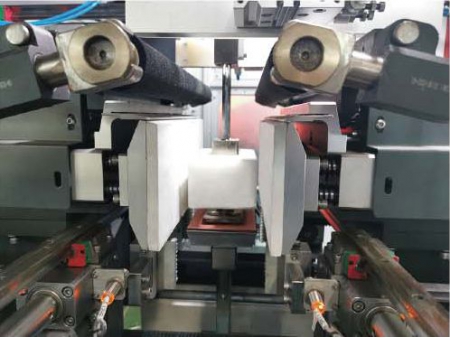

HD Visual Positioning

HD Visual Positioning- HD visual positioning plus YAMAHA-made robotic arm allow the top manufacturing speed of 30 pieces per minute.

- Robotic arm can pick up two boxes at once with positioning accuracy reaching ±0.05 mm.

-

Automatic Box Wrapping

Automatic Box Wrapping- The function of automatic box forming avoids the paper from scratching when pulling the box.

- The cost is lowered as each wrapping head can operate separately.

- The box making machine is fully controlled by servo, allowing easy mode switch in just 5 minutes.

-

Double-Layer Edge Folding

Double-Layer Edge Folding- This rigid box machine is designed with double-layer edge folding which stabilizes the blade, brush and press plate, saving manufacturing costs.

- The box making machine is fully controlled by servo, and each part can be adjusted through the digital display screen. The high accuracy reduces the need for operators to have technical expertise.

-

Full Servo Control

Full Servo Control- The box making machine is fully controlled by servo, reducing the need for operators to have technical expertise.

There are some box making line that we featured for choose your best