Materials

| No. | Part | Material | No. | Part | Material |

| 1 | Valve Body | Cast iron, stainless steel, cast steel, aluminum bronze. | 7 | Worm Gear | Cast Iron |

| 2 | Valve Disc | QT450 Nickel Plated, QT450 Nylon Coated, Aluminum Bronze, Stainless Steel 304, Stainless Steel 316, Stainless Steel 316L, Stainless Steel 2507, Stainless Steel 1.4469, and Stainless Steel 1.4529. | 8 | Bolts | 45#, Stainless Steal |

| 3 | Valve Seat (Rubber) | EPDM, NBR, FTFE, silicone, fluoroelastomer, heat-resistant EPM, and wear-resistant EPM | 9 | Retaining Ring | 50# Mangalloy |

| 4 | Upper Stem | 45#, 304, 316, 420 Stainless Steel | 10 | Thrust Washer | 45# Galvanized Steel |

| 5 | Lower Stem | 45#, 420 Stainless Steel | 11 | Gasket | 45#Galvanized Steel |

| 6 | Retaining Rod | UPVC, 45# | 12 | Lubricating Sleeve | PTFE |

Specifications

| Size | ØD | ØD1 | ØD2 | ØD3 | n-Ød1 | n-Ød2 | H1 | H2 | H3 | M*M | L |

| DN40 | 110 | 72 | 50 | 150 | 4-Ø18 | 4-Ø7 | 76 | 136 | 11 | 11*11 | 110 |

| DN50 | 125 | 72 | 50 | 165 | 4-Ø18 | 4-Ø7 | 81 | 142 | 11 | 11*11 | 110 |

| DN65 | 145 | 72 | 50 | 185 | 4-Ø18 | 4-Ø7 | 96 | 146 | 11 | 11*11 | 114 |

| DN80 | 160 | 72 | 50 | 200 | 4-Ø18 | 4-Ø7 | 98 | 152 | 11 | 11*11 | 116 |

| 160 | 200 | 8-Ø18 |

| DN100 | 180 | 92 | 70 | 220 | 8-Ø18 | 4-Ø10 | 111 | 175 | 14 | 14*14 | 129 |

| DN125 | 210 | 92 | 70 | 250 | 8-Ø18 | 4-Ø10 | 128 | 181 | 17 | 17*17 | 142 |

| DN150 | 240 | 92 | 70 | 285 | 8-Ø22 | 4-Ø10 | 143 | 200 | 17 | 17*17 | 142 |

| DN200 | 295 | 125 | 102 | 340 | 8-Ø22 | 4-Ø12 | 172 | 233 | 22 | 22*22 | 154 |

| 295 | 340 | 12-Ø22 |

| DN250 | 350 | 125 | 102 | 395 | 12-Ø22 | 4-Ø12 | 199 | 265 | 22 | 22*22 | 167 |

| 355 | 405 | 12-Ø26 |

| DN300 | 400 | 150 | 125 | 445 | 12-Ø22 | 4-Ø14 | 231 | 298 | 27 | 27*27 | 180 |

| 410 | 460 | 12-Ø26 |

| DN350 | 460 | 150 | 125 | 505 | 16-Ø22 | 4-Ø14 | 253 | 326 | 27 | 27*27 | 192 |

| 470 | 520 | 16-Ø26 |

| DN400 | 515 | 175 | 140 | 565 | 16-Ø26 | 4-Ø18 | 266 | 367 | 40 | 36*36 | 218 |

| 525 | 580 | 16-Ø30 |

| DN450 | 565 | 175 | 140 | 615 | 20-Ø26 | 4-Ø18 | 299 | 408 | 40 | 36*36 | 224 |

| 585 | 640 | 20-Ø30 |

| DN500 | 620 | 210 | 165 | 670 | 20-Ø26 | 4-Ø22 | 327 | 434 | 50 | 46*46 | 231 |

| 650 | 715 | 20-Ø33 |

| DN600 | 725 | 210 | 165 | 780 | 20-Ø30 | 4-Ø22 | 385 | 506 | 50 | 46*46 | 270 |

| 770 | 840 | 20-Ø36 |

| DN700 | 840 | 300 | 254 | 895 | 24-Ø30 | 8-Ø18 | 456 | 556 | 70 | 64*64 | 293 |

| 840 | 910 | 24-Ø36 |

| DN800 | 950 | 300 | 254 | 1015 | 24-Ø33 | 8-Ø18 | 487 | 604 | 70 | 64*64 | 318 |

| 950 | 1025 | 24-Ø39 |

| DN900 | 1050 | 300 | 254 | 1115 | 28-Ø33 | 8-Ø18 | 555 | 688 | 80 | 74*74 | 328 |

| 1050 | 1125 | 28-Ø39 |

| DN1000 | 1160 | 300 | 254 | 1230 | 28-Ø36 | 8-Ø18 | 621 | 738 | 80 | 74*74 | 413 |

| 1170 | 1255 | 28-Ø42 |

| DN1200 | 1380 | 350 | 298 | 1455 | 32-Ø39 | 8-Ø22 | 775 | 925 | 90 | 84*84 | 473 |

| 1390 | 1485 | 32-Ø48 |

Certifications

| Item | Standard | Optional Standard |

| Design & Manufacture | GB12238-89 | ISO/DIN10631-91, AP1598 |

| Face to Face Dimension | GB12221-89 | ISO5752-88 |

| Flange Connection | GB9113.1-2000, GB/T9119-2010 | ANSI.B16.5, ISO7005, JIS2220:2004, DIN2532 |

| Valve Test | GB/T13927-92 | ISO/DIN 5208-87 |

| Valve Mark | GB12220-89 | ISO/DIN 5209-87 |

| Valve Supply Requirements | GB/T12252 | / |

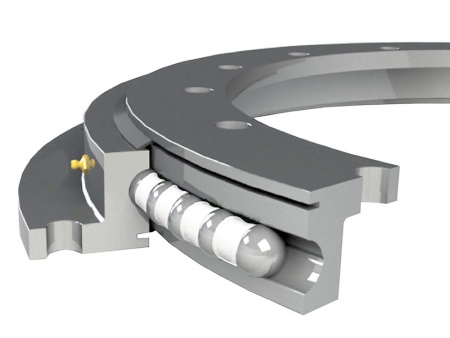

Secure Flange Connection

Flanged butterfly valves feature a raised surface on valve components that securely fits into a corresponding groove on the opposing surface, ensuring a reliable connection.

Ideal for Heavy-Duty Pipelines

The design of flanged butterfly valves makes them well-suited for heavy-duty pipeline applications where durability and dependability are crucial.

Versatile Performance

Crafted with high-quality materials and optimized design, our flanged butterfly valves exhibit excellent performance in both commercial and industrial settings, even in extreme temperature conditions.