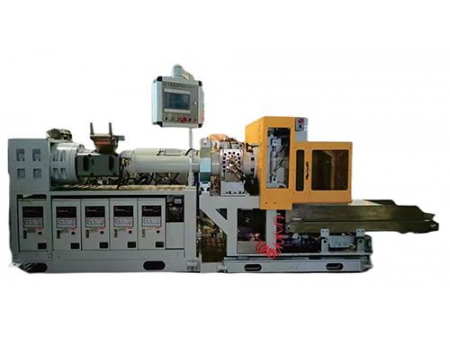

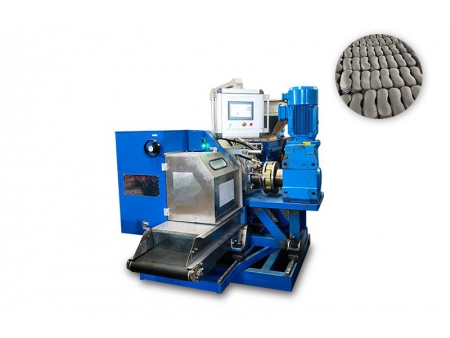

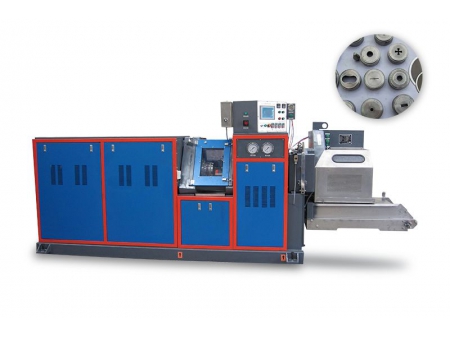

Rubber extrusion is a process used to manufacture rubber products. This process involves using an extruder with various shaping dies to form primary rubber products of different shapes under high pressure.

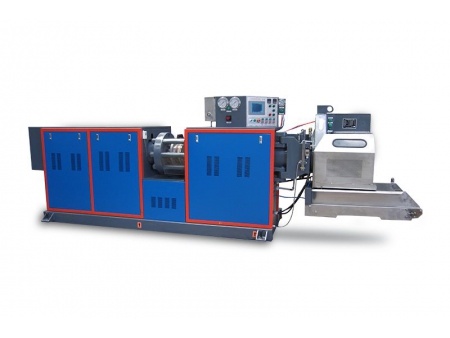

In hot feed preforming, the rubber strip fed into the machine must be preheated and plasticized on a rubber mill before processing.

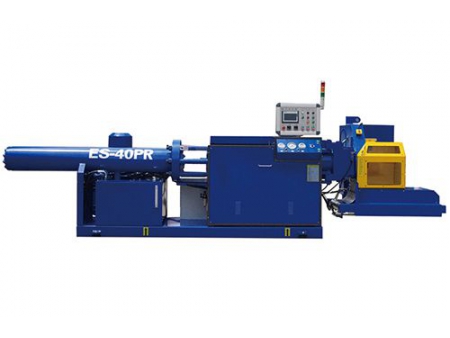

In cold feed preforming, the rubber strip does not require heating and is directly fed into the extruder.