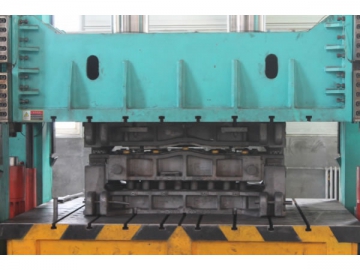

Hydraulic Press for Automotive Parts Molding

After years of research and development, our technical engineers and designers successfully produced our hydraulic press for automotive parts molding, featuring high precision, low failure rate and compact structure. In order to satisfy the ever increasing market demands, we already launched many series of hydraulic presses for the molding of different automotive parts. This kind of hydraulic press has save a lot of time and labor cost for our customers and received consistent praise.

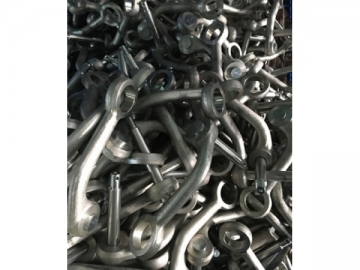

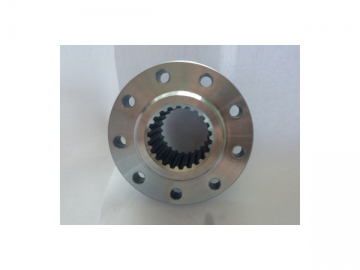

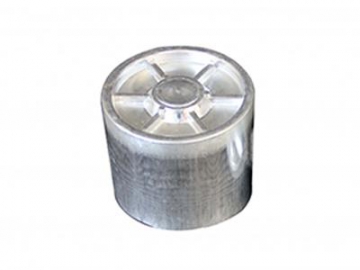

Shown here is our hydraulic press and some molded automotive parts.

Technical Parameters of Hydraulic Automotive Press Molding force: 200KN~63000KN

Max size of workpiece: 7000*4000mm

Workpiece thickness: 0.25~16mm

Attractive Advantages 1. For this hydraulic press, we’ve designed many series and types to meet the molding requirements of various automotive components and parts on the market.

2. A standard frame and smooth guide rail ensures the normal running and high precision.

3. For shock pulses, we adopt an effective hydraulic buff system, which increases the operating stability as well as decreases the vibration and noise.

4. A flexible adjustment of the working pressure ensures our hydraulic press functions well while processing different workpieces.

5. The operation window is equipped with a grating in consideration of operating security.

6. High frequency response hydraulic system achieves a remarkable increase in working efficiency.

7. We independently developed our control system, combining the setting and displaying of many technical information, such as system pressure, I/O interface, fault diagnosis and to name a few.

8. Hydraulic press produced by JIASHESNG is the most ideal choice for molding of car clutches, truck parts, car rear axles, etc.

9. Our presses are widely utilized for blanking, drawing and stamping of various components and parts.

| Item | Unit | | | | | |

| Nominal force | KN | 2000 | 2500 | 3150 | 4000 | 5000 |

| Return force | KN | 400 | 500 | 800 | 900 | 1000 |

| Force of hydraulic cushion | KN | 400 | 1000 | 1500 | 1500 | 2000 |

| Blanking force | KN | 400 | 500 | 800 | 1500 | 1600 |

| Max height | mm | 1120 | 1200 | 1250 | 1250 | 1500 |

| Rated hydraulic pressure | Mpa | 25 | 25 | 25 | 25 | 25 |

| Stroke of sliding block | mm | 800 | 900 | 1000 | 1000 | 1200 |

| Stroke of hydraulic cushion | mm | 200 | 200 | 220 | 250 | 300 |

| Stroke of working platform | mm | 800 | 900 | 1000 | 1500 | 1600 |

| Stroke of blanking regulator | mm | 100 | 100 | 150 | 150 | 200 |

| Bearing capacity of working platform | T | 10 | 10 | 10 | 15 | 15 |

| Motor power | Kw | 7.5 | 11 | 22 | 30 | 52.5 |

| Height of working platform | mm | 300 | 300 | 350 | 400 | 500 |

| Speed of empty trip | mm/s | 80-120 | 80-120 | 100-120 | 100-120 | 100-120 |

| Speed of sliding block | mm/s | 8--18 | 8--20 | 8--20 | 10--20 | 10--20 |

| Speed of return trip | mm/s | 80-120 | 80-120 | 100-120 | 100-120 | 100-120 |

| Ascending speed of hydraulic cushion | mm/s | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 |

| Descending speed of hydraulic cushion | mm/s | 60-70 | 60-70 | 60-70 | 60-70 | 60-70 |

| Length of working plate | mm | 1000 | 1250 | 1500 | 2000 | 2800 |

| Width of working plate | mm | 800 | 900 | 1000 | 1500 | 1600 |

| Length of hydraulic cushion | mm | 600 | 800 | 1000 | 1400 | 2200 |

| Width of hydraulic cushion | mm | 500 | 600 | 700 | 1100 | 1000 |

| Item | Unit | | | | | |

| Nominal force | KN | 6300 | 8000 | 10000 | 12500 | 16000 |

| Return force | KN | 1200 | 1500 | 1760 | 2000 | 2200 |

| Force of hydraulic cushion | KN | 2500 | 3000 | 4000 | 5000 | 6000 |

| Blanking force | KN | 2000 | 2500 | 3000 | 4500 | 6000 |

| Max height | mm | 1600 | 1800 | 1800 | 1800 | 2000 |

| Rated hydraulic pressure | Mpa | 25 | 25 | 25 | 25 | 25 |

| Stroke of sliding block | mm | 1200 | 1400 | 1400 | 1400 | 1400 |

| Stroke of hydraulic cushion | mm | 350 | 350 | 400 | 400 | 450 |

| Stoke of working platform | mm | 1700 | 2000 | 2200 | 2200 | 2200 |

| Stroke of blanking regulator | mm | 200 | 200 | 200 | 200 | 250 |

| Bearing capacity of working platform | T | 20 | 20 | 30 | 30 | 30 |

| Motor power | Kw | 57 | 68.5 | 82.5 | 98.5 | 122.5 |

| Height of working platform | mm | 450 | 500 | 500 | 600 | 650 |

| Speed of empty trip | mm/s | 100-150 | 180-220 | 180-220 | 180-220 | 200-250 |

| Speed of sliding block | mm/s | 10--20 | 10--20 | 10--20 | 12--25 | 12--25 |

| Speed of return trip | mm/s | 100-150 | 150-180 | 150-180 | 150-180 | 180-200 |

| Ascending speed of hydraulic cushion | mm/s | 50-60 | 50-60 | 50-60 | 60-70 | 60-70 |

| Descending speed of hydraulic cushion | mm/s | 60-80 | 60-80 | 60-80 | 80-100 | 80-100 |

| Length of working platform | mm | 3000 | 3800 | 4000 | 4000 | 4500 |

| Width of working platform | mm | 1800 | 2000 | 2200 | 2500 | 2800 |

| Length of hydraulic cushion | mm | 2200 | 3000 | 3200 | 3200 | 3600 |

| Width of hydraulic cushion | mm | 1200 | 1400 | 1600 | 1900 | 2200 |

| Item | Unit | | | | | |

| Nominal force | KN | 6300 | 6300 | 5000 | 5000 | 3150 |

| Return force | KN | 1200 | 1200 | 1000 | 1000 | 600 |

| Force of hydraulic cushion | KN | 2500 | 2500 | 2500 | 2500 | 1000 |

| Blanking force | KN | 2000 | 2000 | 2000 | 2000 | 2000 |

| Max height | mm | 1700 | 1600 | 1600 | 1700 | 1250 |

| Rated hydraulic pressure | Mpa | 25 | 25 | 25 | 25 | 25 |

| Stroke of sliding block | mm | 1200 | 1100 | 1100 | 1200 | 800 |

| Stroke of hydraulic cushion | mm | 350 | 350 | 350 | 350 | 300 |

| Stroke of working platform | mm | 1550 | 2050 | 2050 | 1550 | 1450 |

| Stroke of blanking regulator | mm | 200 | 200 | 200 | 200 | 200 |

| Bearing capacity of working platform | T | 20 | 20 | 20 | 20 | 20 |

| Motor power | Kw | 52.5 | 52.5 | 52.5 | 52.5 | 47 |

| Height of working platform | mm | 580 | 580 | 580 | 580 | 450 |

| Speed of empty trip | mm/s | 120-150 | 120-150 | 120-150 | 120-150 | 120-180 |

| Speed of sliding block | mm/s | 10--20 | 10--20 | 10--20 | 10--20 | 10--20 |

| Speed of return trip | mm/s | 100-120 | 100-120 | 100-120 | 100-120 | 100-120 |

| Ascending speed of hydraulic cushion | mm/s | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 |

| Descending speed of hydraulic cushion | mm/s | 60-80 | 60-80 | 60-80 | 60-80 | 60-80 |

| Length of working platform | mm | 2500 | 3000 | 3000 | 2500 | 2000 |

| Width of working platform | mm | 1500 | 2000 | 2000 | 1500 | 1400 |

| Length of hydraulic cushion | mm | 1500 | 2200 | 2200 | 1500 | 1450 |

| Width of hydraulic cushion | mm | 900 | 1300 | 1300 | 900 | 820 |