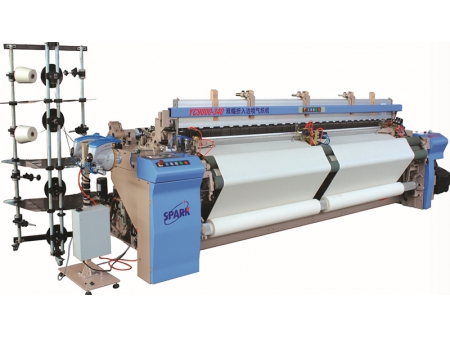

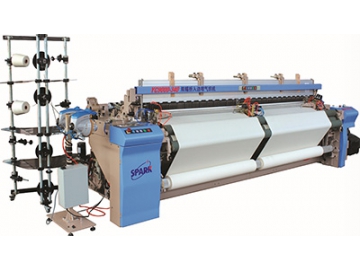

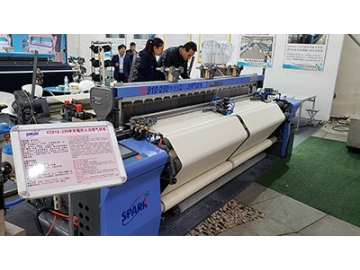

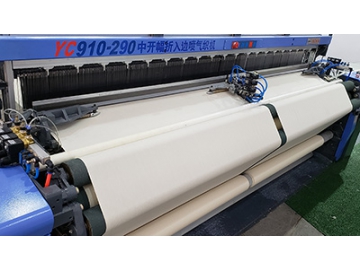

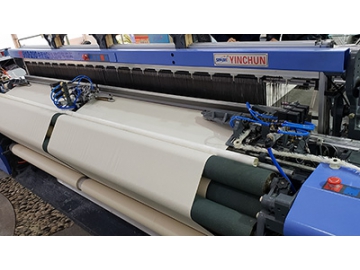

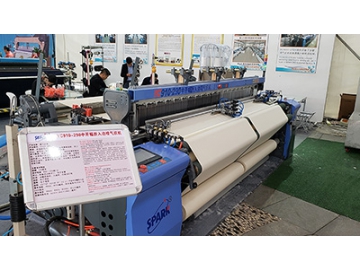

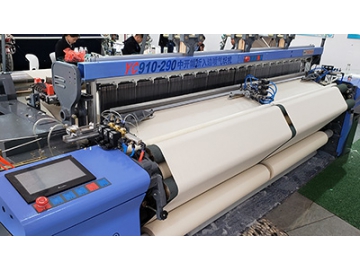

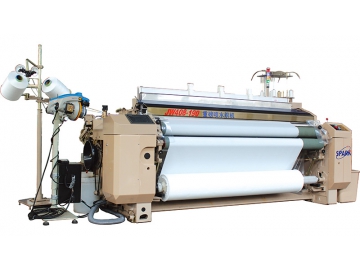

YC9000 Air jet loom

Request a Quote

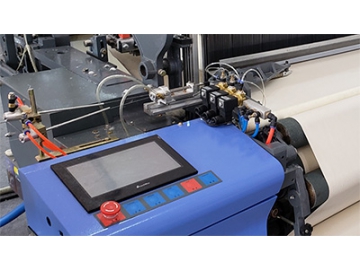

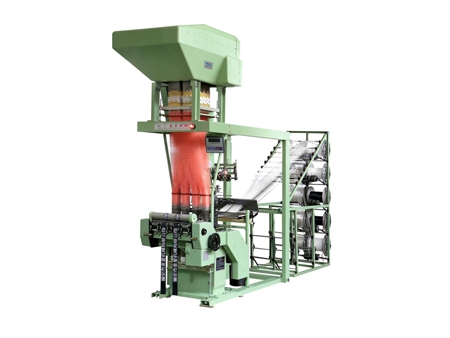

The YC9000 air jet loom is an efficient weaving machine, capable of achieving a high-speed selvedge folding in combination with weaving functions. The fabric selvedge folding unit cuts the woven fabric through the middle, then folds up the four edges to create four smooth and flat hems. The air jet weaving loom features a high working efficiency, stable performance, and precise time control, making it ideal for processing medium-width fabrics. This air jet weaving machine meets the needs of fabrics with complex structures and aesthetics.

Features

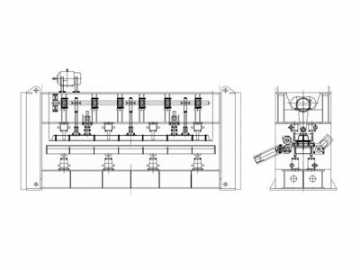

- The pneumatic fabric selvedge folding unit can create a folded hem with a narrow width of 0.8cm. Compared to mechanical selvedge folding devices, the pneumatic device reduces the air consumption by 30% and improves the efficiency by as much as 95%.

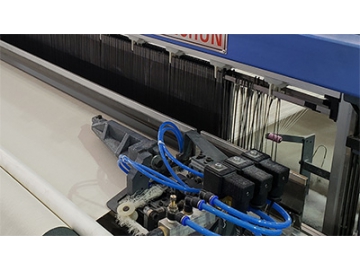

- The advanced electronic control system ensures easy operation while four different weft insertion modes allow the air jet loom to adjust according to various production needs, thus significantly improving production adaptability and flexibility.

- Powerful 64-bit CPU provides precise synchronous device control, including let-off and take-up mechanisms. Optimized taper angles on the sub nozzles allow for a faster and more stable weft insertion at a lower air consumption.

- The electronic control pneumatic selvedge folding system can adapt to different selvedges (no rough or waste selvedge). The air jet loom delivers an excellent weaving efficiency at a lowest air consumption, greatly reducing your weaving cost.

Machine specifications

| Item | Specifications | Spare Parts | |

| Reed Width | Nominal | 150, 170, 190, 210, 230, 250, 280, 340, 360, 390 | |

| Effective | Nominal: 0~60cm (150-250) 0~80cm (>280) | ||

| Weaving Range | Short fiber: ne 160-ne 2.5 Filament: 22 D- 1350 D | ||

| Weft selection | 1, 2, 3, 4 & 6 Colors | ||

| Motor | Start mode | Super speed start | |

| Press the start/stop button to slow action forward/rear | |||

| Press the link& start button at the same time to start | |||

| Power | 2.8kw, 3.0kw, 3.7kw, 4.5kw, 5.5kw | ||

| Weft insertion | Method | Main nozzle Swing Nozzle Sub nozzle U type reed | WBS(Weft brake system) |

| Control | Import high frequency sub nozzle/ computer program control | ||

| Sub nozzle | Integrated flow sub nozzle | ||

| Feeder | Electric control loop feeder | Balloon prevent device | |

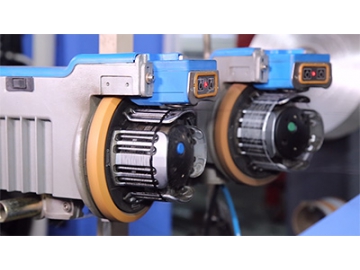

| Beating | Beating motion | Dual oil bath box type 4-bar/ 6bar/ eccentric beating motion | |

| Solid beating system | |||

| Multi support brick and balance weight | |||

| Shedding | Crank/ Plain shedding | ||

| Cam shedding | |||

| Electronic Jacquard shedding | |||

| Dobby Shedding | Upper dobby shedding | ||

| Let Off | Electric servo let off | Double Warp Beam | |

| Dual back beam | |||

| Positive/ negative let off | |||

| Flange dia. | 800, 914, 1000 mm | ||

| Take up | Take up | Electric servo/ mechanical take-up | |

| Fabric rolling | Inside rolling (Max. 600mm)/ Outside rolling | ||

| Temple | Upper/ underneath | ||

| Selvedge | Dual sides planet selvedge/ electric | ||

| Lubrication | Motion box is oil bath, others are centralized lubricating | ||

| Shut down device | Weft breakage | Reflecting double sensor W1, W2 | |

| Warp breakage | Control system warp break detector, LED display | ||

| Others | Selvedge yarn/ yarn end break stop motion | ||

| Shutdown display | Screen display, multi- function shutdown display lights | ||

| Weft cutter | Mechanical cutter, electronic cutter | ||

| Electric control system | High resolution large VGA color touch display, DSP motherboard, WIFI connect. | ||

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos