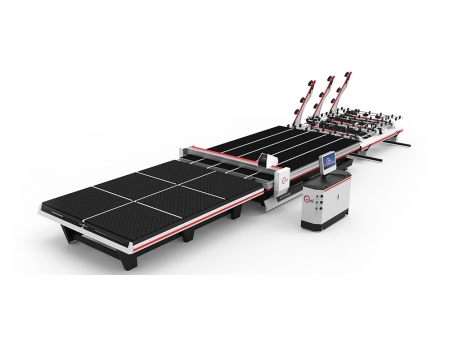

Breaking Machine

Request a Quote

JZD-X-I

JZD-X-II

JZD-X-III

JZD-X-IV

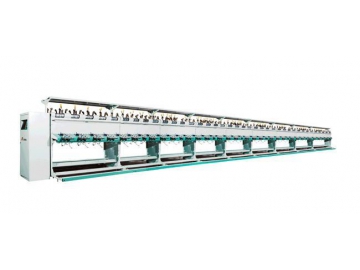

JZD-X-I: Single-side breaking of carrier

JZD-X-II: Double-bridge breaking of flat carrier

JZD-X-III: Double-bridge breaking after preforming

JZD-X-IV: Double-bridge breaking of cantilevered seal flat carrier

Applications

Breaking machine is used for breaking the carrier of composite rubber seals.

Features

Safe, durable, easy to operate.

Breaking Machine (Fatigue breaking)

| Model | |

| Dimensions | L3800×W1000×H2000mm |

| Speed Control | Swing rod |

| Conveyor Speed | 3~35m/min, variable frequency speed regulation |

| Traction Method | Belt puller |

| Breaking Method | Fatigue |

| Motor | One variable frequency motor is used for both traction and breaking. |

| Breaking Principle | The upper part has 13 power rotating shafts and the lower part has 12 non-power rotating shafts mounted on 12 cylinders. Before operation, the cylinders lift the 12 rotating shafts to a position above the upper 13 rotating shafts. When the rubber strip passes through the upper 13 rotating shafts, the cylinders press the 12 shafts down to the lower stop point, causing the rubber strip to pass around the 25 shafts separately. The equipment is equipped with a puller, and the rubber strip travels around the 25 shafts in both forward and reverse directions under the traction of the puller, ultimately breaking the steel strip. |

Breaking Machine (Crush & stretch breaking off)

| Model | |

| Dimensions | L2000×W1000×H2000mm (subject to final design drawings) |

| Power | The export traction motor is 0.75kW, and the main motor power is 3kW. |

| Conveyor Speed | 2-25m/min, variable frequency speed regulation |

| Speed Control | The equipment is equipped with a displacement sensor for speed control at the entrance, which automatically adapts to the line speed. |

| Working Principle | The equipment consists of a traction device, frame, breaking assembly, electrical control box, operating box, and swing rod device. The traction device is composed of gear transmission and cam mechanism. After pressing the product, it drags the product from right to left. The breaking wheel device consists of a cam, follower, and chain drive system. It repeatedly bends the rubber product with a steel core, causing the steel core to fatigue and break. The speed of the traction device's conveying wheel is controlled by variable frequency speed regulation, and the speed control motor is controlled by the swing rod, thus achieving automatic control of material conveying speed. |

| Note | The buyer needs to provide a cross-sectional diagram of the rubber product. |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos