CNG Tube (for Jumbo Tube Trailer), ISO 11515

Advantages of the Composite CNG Tube

1. Advanced Technique, High Safety and Reliable Quality

Top-notch wrapping technology and fatigue strength design can realize stable and uniform fiber tension. It also effectively overcomes the problem of fatigue failure when in use of large-diameter long pipes.

The rotational speed of the composite tube is controlled by a microprocessor in a curing oven, which can prevent the liquid resin from flowing and also realize a highly uniform curing process. By doing so, we can obtain a high-quality resin matrix to ensure high safety and reliability of CNG pipes.

Before a hydrostatic test is started, the metal liner and composite layer must be very tightly connected together so as to extend the fatigue life of the composite CNG tube.

Built to meet ISO 11515:2013 standard, the composite jumbo tube will withstand the following tests.

Hydrostatic test and volumetric expansion test

Liner burst test

Jumbo tube burst test

Cyclic pressure testing at normal temperature and extreme temperature

Blunt impact test

Fire test

Coating test

Salt spray test

By simulating the working conditions of our composite CNG tube, the above-mentioned tests effectively guarantee high safety and stability of the trailer tube.

2. Light Weight and Superb Gas-Carrying CapacityA Comparison between Our Composite Jumbo Tube Trailer and the Commonly Used Tube Trailer from Other Manufacturers

| Manufacturer | Cylinder number | Cylinder material | Water volume (L) | Working pressure (Mpa) | Filling gas volume (m 3) | Cylinder weight (Kg) | Total weight (Kg) | Full load weight (Kg) | Weight/volume ratio (weight / volume) |

| A | 8 | Steel | 17600 | 25 | 5174 | 23800 | 27200 | 30912 | 1.55 |

| B | 8 | Steel | 18000 | 20 | 4234 | 22240 | 26010 | 29047 | 1.45 |

| Sinoma | 12 | Steel carbon fiber | 26760 | 25 | 7867 | 20400 | 24862 | 30506 | 0.93 |

Sinoma composite jumbo tube trailer has the lowest total weight.

Sinoma composite jumbo tube trailer can offer the highest volume of filling gas.

Sinoma composite jumbo tube trailer's weight-volume ratio reaches 0.93.

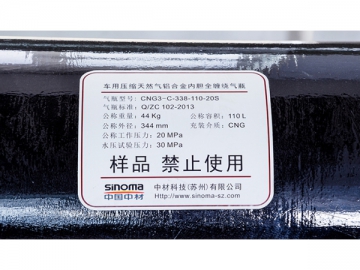

Specifications of the Composite CNG Tube

| Standard | Model | Working temperature (℃) | Working pressure (MPa) | CNG tube | Jumbo tube container | Dimensions (L× W× H) (mm) | ||||||

| Outer diameter (mm) | Length (mm) | Weight (Kg) | Total water volume (m 3 ) | Total filling gas volume (Nm 3) /(20℃) | Total filling gas weight (Kg) | Empty container weight (Kg) | Total weight of container (Kg) | |||||

| ISO 11515 | -40~60 | 25 | 559 | 5360 | 832 | 10.45 | 3266 | 2319 | 11435 | 13754 | 6058× 2438× 2128 | |

| 5360 | 832 | 11.50 | 3592 | 2550 | 12284 | 14834 | 6058× 2438× 2128 | |||||

| 5360 | 832 | 12.54 | 3919 | 2782 | 13132 | 15914 | 6058× 2438× 2128 | |||||

| 5360 | 832 | 13.59 | 4245 | 3014 | 14181 | 17195 | 6058× 2438× 2625 | |||||

| 5360 | 832 | 14.63 | 4572 | 3246 | 15029 | 18275 | 6058× 2438× 2625 | |||||

| 5360 | 832 | 15.68 | 4898 | 3478 | 15878 | 19355 | 6058× 2438× 2625 | |||||

| 5360 | 832 | 16.72 | 5225 | 3710 | 16726 | 20436 | 6058× 2438× 2687 | |||||

| 10950 | 1700 | 22.30 | 6969 | 4948 | 21450 | 26398 | 12192× 2438× 2128 | |||||

| 10950 | 1700 | 24.53 | 7666 | 5443 | 23170 | 28613 | 12192× 2438× 2128 | |||||

| 10950 | 1700 | 26.76 | 8363 | 5937 | 24890 | 30827 | 12192× 2438× 2128 | |||||

| 10950 | 1700 | 28.99 | 9059 | 6432 | 27010 | 33442 | 12192× 2438× 2625 | |||||

| 10950 | 1700 | 31.22 | 9756 | 6927 | 28730 | 35657 | 12192× 2438× 2625 | |||||

| 10950 | 1700 | 33.45 | 10453 | 7422 | 30450 | 37872 | 12192× 2438× 2625 | |||||

| 10950 | 1700 | 35.68 | 11150 | 7917 | 32170 | 40087 | 12192× 2438× 2687 | |||||