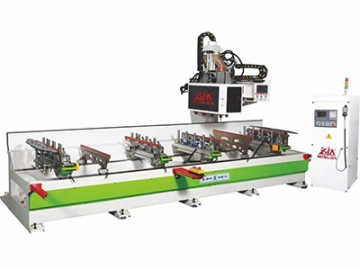

Combined CNC Milling & Turning Center (Two Stations)

Request a Quote

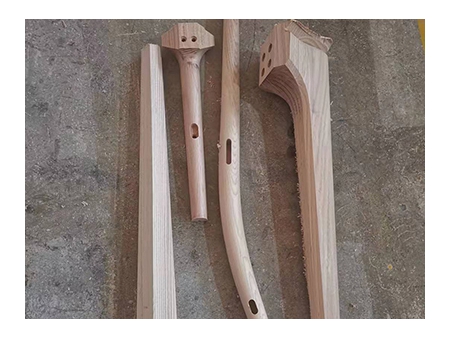

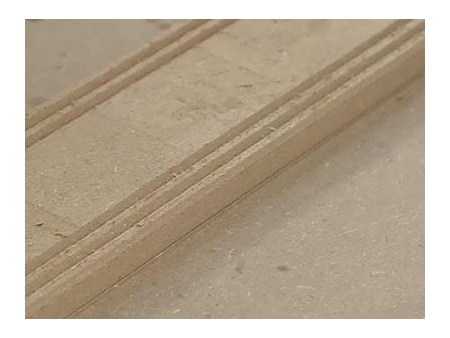

The combined CNC milling & turning center of two stations is a machining center combining 16 cutting tools which can be used for vertical milling, wire bonding, hole drilling, slot broaching and rounding. The CNC turning and milling machine has two stations working in turn to process 4 wood workpieces simultaneously. The woodworking machine can be used to make all kinds of wood furniture more efficiently.

Features- The CNC control system supports the machine’s general purposes by directing the production processes like slot broaching and hole drilling to ensure the one-shot product forming.

- The design of two working stations helps the machine run constantly and improve the efficiency.

- The machine frame made of annealed steel is solid and durable.

| Model | MD-1000D4S |

| Max. processing length | 1000mm |

| Max. processing width | 180mm |

| Max. processing thickness | 180mm |

| X axis servo motor | 2.3kW |

| Y1 axis servo motor | 1.5kW |

| Y2 axis servo motor | 1.5kW |

| Z axis servo motor | 1.5kW |

| C axis servo motor | 0.85kW |

| A1 axis servo motor | 0.85kW |

| A2 axis servo motor | 0.85kW |

| Spindle motor | 5.5kW*4 (ER32 ⌀ 25mm) 3.7kW*4 (ER25) |

| Control system | LNC |

| Programming | UG |

| Distance between table top and spindle nose in vertical position | 300mm |

| Total power | 46kW |

| Voltage | 380V |

| Air pressure | 0.8MPa |

| Work table type | Shuttle table |

| Mechanical dimensions | 4100*2300*2050mm |

| Total weight | 5000kg |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos