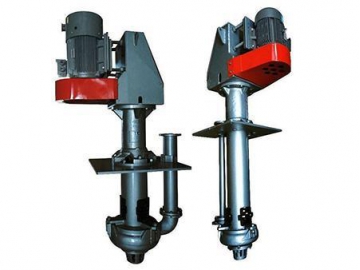

SSD Slurry Pump (Submersible Centrifugal Pump)

Working Conditions

1. Power supply: 380V, 3PH, 50Hz;

2. Medium:containing no combustible gas and the temperature should be no higher than 40°C,maximum medium density: 1.2kg/L, PH: 6-9;

3. Solid particles: maximum mass percent: 30%;

4. Maximum depth: 20m;

Technical Specifications

Diameter of outlet: 50~300mm

Flow rate: 40~1000m3/h

Head of a single stage: 15-60m

Based on our research on the market needs and our customers’ feedbacks, we have provided this SSD submersible slurry pump , vertical single-stage slurry pump that is featured with motor and pump which are co-axial, advanced structure, wide flow passage and excellent drainage capacity. Made of quality materials, it is highly resistant to corrosion and could work smoothly as it is submerged in liquid.

Structural Features of Submersible Slurry Pump

1. This submersible pumping equipment is designed and manufactured with advanced technologies introduced from overseas countries. Made of abrasion-resistant materials, it enjoys an significantly expanded service lifespan and requires much less maintenance;

2. Aside from the main impeller, this submersible centrifugal pump is also equipped with mixer impeller which could stir up the deposited slurries and promote the conveyance;

3. Its independent mechanical sealing device could perfectly keep the external and internal pressures of the oil cavity balanced and ensure the sealing effect, significantly expanding the equipment’s service life;

4. This industrial slurry pump could automatically start the over-heating devices, water-proof protectors as well as other protection devices to ensure its smooth and safe operations under harsh conditions;

5. Such reliable protection devices as the anti-fogging device for the motor and bearing temperature protection device are available for customers now.

Application of Submersible Slurry Pump

This slurry handling unit could be used to transport dust, slurry, sand and mud in the metallurgical, mining, steel manufacturing, power generation industries.