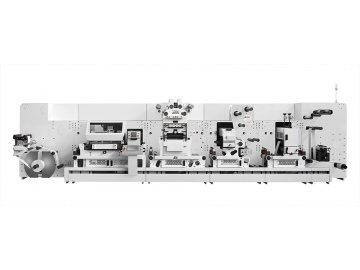

Servo Driven Four-Color Screen Printing Machine, JS-412UVT

Request a Quote

Screen printer for round, oval, square, conical and flat containers

Screen printer for round, oval, square, conical and flat containers

Equipped with servo motors, JS-412UVT is a 12-station rotary printing machine designed for four-color printing. Thanks to its features, this industrial printing equipment can be used to print on products with various shapes and sizes, ranging from 15 to 100 mm, making it a highly efficient choice for diverse industrial printing needs.

Specifications

- Printing Product Size (Diameter × Length): (15-100mm)×(20-200mm)

- Maximum Printing Speed: 50pcs/min

- Power Supply: 380V 3phase 50HZ

- Compressed Air Pressure: 4-6bar

- Power Consumption: 35kW

- Machine Dimensions (L×W×H): 3000×3000×1900mm

- Weight: 3600kg

Applications

- Suitable for the cosmetics industry to achieve beautiful prints on lipstick and mascara tubes.

- Capable of high precision printing on electronic devices.

- In the medical sector, the screen printer is perfect for accurate printing on medical consumables and pharmaceutical packaging.

- It meets the needs of the food packaging industry with attractive and informative prints on packaging boxes.

- For the beverage industry, this screen printing machine is ideal for creating eye-catching labels and designs on beverage bottles.

Variety of printable shapes

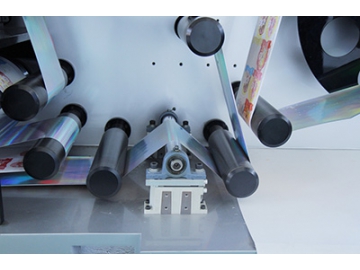

This screen printer is capable of printing on a wide range of shapes, including round, curved, square, flat, and conical bottles, offering four-color printing versatility.

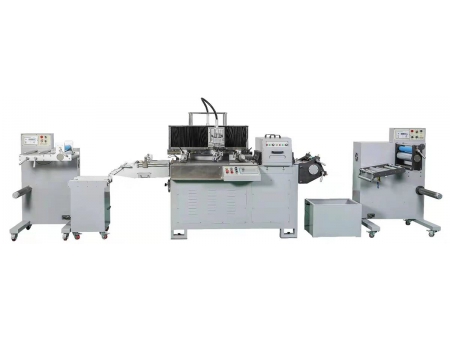

Supports three types of printing methods

- Single-color hot stamping with two-color screen printing.

- Single-color hot stamping with single-color screen printing.

- Single-color hot stamping with three-color screen printing.

Features

- Combines screen printing and hot stamping processes in one machine for greater versatility in print designs.

- The screen printer can easily switch between four printing modes, from mono color to multicolor printing, to suit various project requirements.

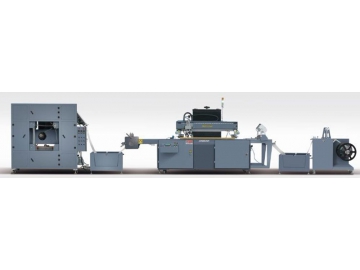

- Equipped with a UV drying system that adapts to different ink types, ensuring quick and effective drying.

- Equipped with a fully servo-driven mechanism to enhance consistency and accuracy in prints, making each output reliable.

- This screen printing press has a twelve-station rotary setup that helps improve printing efficiency without sacrificing quality.

- Includes innovative features like automatic error detection to prevent printing without an item and alerts for operational issues.

- Optional CCD alignment device available for projects needing high precision, ensuring flawless prints every time.

- Optional hot stamping device, adding to this printing equipment’s multifunctional capabilities.

- Our screen printer is capable of printing on a wide range of materials, including plastic, aluminum, and electroplated surfaces.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos