End Mills

End mills are rotary cutting tools with one or more teeth which process the surface, step and slot of various work pieces. Used in milling machines and CNC machining centers, these cutting tools most commonly come as a single flute end mill or double flute end mill and are designed for finish milling or semi-finish milling of wood, graphite, ceramic, aluminum alloy, stainless steel and other materials. We also offer custom end mills and OEM services upon request.

CGI offers various models of these end mills which are used for different applications and CNC machines. They can be classified into several types according to their appearance.

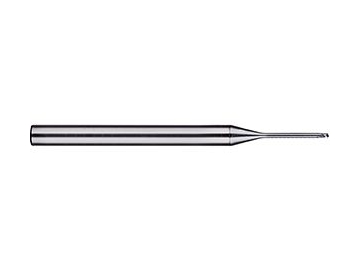

1. Square End Mill

This end mill cuts away large amounts of material and leaves a poor surface finish (roughing). It also mills small horizontal surfaces.

2. Ball Nose End Mill

The ball nose end mill fits for finish and semi-finish milling of curved surfaces. These end mills can process irregular profiles as well as small chamfers of steep surfaces with high precision.

3. Corner Chamfer End Mill

Mainly intended for rough milling, the corner chamfer end mill can finish milling small chamfers of flat surfaces.

4. Profile Milling Cutter

This cutter includes chamfer mill, T-slot cutter, slitting saw and involute gear cutter.

5. Chamfer Mill

Our chamfer mills come in two different types: one mills round chamfers and the other mills inclined chamfers.

6. T-Slot Cutter

This cutter processes T slots.

7. Involute Gear Cutter

This cutter is designed mainly for machining gears.

8. Roughing End Mill

This end mill cuts away large amounts of material in a short time and works particularly well for aluminum or copper alloys.