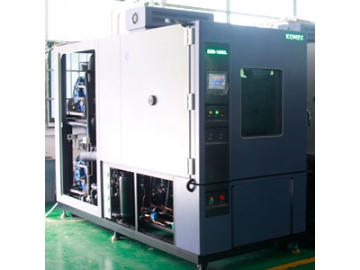

Rapid Temperature Change Humidity Test Chamber

Request a Quote

Technical Characteristics

- Highly reliable and stable imported piston compressor.

- Condensate water temperature and water pressure sensor; pre-warning and warning functions against abnormal water circuit.

- Multi-point temperature control function; multiple optional test piece sensors to control temperature at air outlet, center point, max., min. or average temperature control of test pieces.

- Imported high-precision capacitive humidity sensor with Grade A precision PT100 to realize higher temperature and humidity measurement accuracy.

- The test chamber can judge the program jump time automatically, store energy in advance, and enable refrigeration immediately in cooling section on the premise of ensuring energy conservation without waiting for pressure reduction and energy storage of the refrigeration system.

- A wide range of temperature and humidity control; relative humidity: 15%~95%RH (no heat source in working space during damp heat test). Temperature range: 10℃~95℃ (low temperature auxiliary system can be added to satisfy the requirements for low temperature).

- Able to switch among various algorithms automatically such as energy pre-input, overshoot suppression, automatic rate matching of linear temperature rise and drop, etc., to ensure the equipment’s excellent linear following function, and compliance with the fluctuation range (<0.5℃) and temperature overshoot (<2℃).

Technical Parameters

| Rapid Temperature Change Humidity Test Chamber -70℃ ~ 180℃/10%~98%RH/5℃/min~15℃/min | ||||||

| Specifications & Model | ||||||

| Internal Volume | 500L | 1,000L | 1,500L | 2,000L | ||

| Overall Dimensions | Internal Dimensions (W×D×H) | 850×700×850mm | 1,000×1,000×1,000mm | 1,150×1,150×1,150mm | 1,200×1,400×1,200mm | |

| External Dimensions (W×D×H) | 1,100×2,605×2,140mm | 1,250×2,995×2,260mm | 1,900×3,800×2,000mm | 2,000×3,715×2,200mm | ||

| Performance | Temperature Range | -70℃~ 180℃ | ||||

| Fluctuation Range of Temperature | ≤ 0.5℃ (no-load steady state) | |||||

| Temperature Deviation | ≤ 2℃ (no-load steady state) | |||||

| Temperature Uniformity | ≤2℃ (no-load steady state) | |||||

| Humidity Range | 10%RH~98%RH (No heat source during damp heat test) | |||||

| Relative Humidity Deviation | ≤±3%RH(>75%RH,no-load steady state) ≤±5%RH(≤75%RH,no-load steady state) | |||||

| Relative Humidity Fluctuation | ≤±3%RH | |||||

| Wind Speed at Central Point | ≤1.7m/s (equipped with adjustable wind speed inverter) | |||||

| Temperature and Humidity Control Mode | Hot gas bypass technology | |||||

| Temperature Change Rate | Heating rate:1~15℃/min (-55 ℃ ~ 85 ℃,average throughout,measured at the air outlet,no load) Cooling rate:1~15℃/min ( 85℃ ~-55 ℃,average throughout,measured at air outlet,no load) | |||||

| Constitution | Shell mMterial | Cold-rolled steel sheet with plastic powder coating | ||||

| Test Area Materials | SUS304 stainless steel with mirror finish,the gaps are fully welded by TIG (tungsten inert gas arc welding) | |||||

| Heater | Nichrome wire heater | |||||

| Cooler (Dehumidifier) | Mechanical dehumidification | |||||

| Circulating Fan | Axial fan | |||||

| Air Dryer | Adsorption of refrigeration drying air | |||||

| Water Supply | Water Supply Mode | Pumped water supply system and manual water filling | ||||

| Water Supply Tank | 24L | |||||

| Refrigeration System | Refrigerating Machine | Piston compressor | ||||

| Refrigerant | Environment-friendly refrigerant HFC R404a R23 | |||||

| Equipment Requirements | Ambient Conditions | 5~ 30℃ /relative humidity≤85%RH | ||||

| Power Supply | 380V±38V/50Hz N G | |||||

| Total weight of tank | Approx. 1,500kg | Approx. 2,000kg | Approx. 2,500kg | Approx. 3,000kg | ||

| Applicable standards | GB/T 2423.1-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Methods-Tests A:Cold GB/T 2423.2-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Methods-Tests B:Dry Heat GB/T 2423.3-2008 Environmental Testing for Electric and Electronic Products-Part 2:Testing Method- Test CaB:Damp Heat,Steady State GB/T 2423.4-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Method-Test Db:Damp Heat,Cyclic (12h 12h cycle) GJB 150.3A-2009 Laboratory Environmental Test Methods for Military Materiel-Part 3:High Temperature Test GJB 150.4A-2009 Laboratory Environmental Test Methods for Military Materiel-Part 4:Low Temperature Test | |||||

| Applicable Measurement Standard | JJF 1270-2010 Calibration Specification for Temperature/Humidity/Vibration Combined Environmental Testing System (the temperature and humidity indicators in the standard) | |||||

Notes:

- The range of temperature and humidity above is the results tested at an ambient temperature of 20℃ (room temperature) or cooling system water temperature of 25℃ and with no any load.

- Measurement was made as per the test method of IEC 60068-3-6: 2001/GB/T 2424.6-2006/JMT K09: 2009 based on the effective space formed with a distance of 1/10 to each edge in the internal box.

- The pictures and specifications above are for reference only. The specific specification is subject to quotation.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos