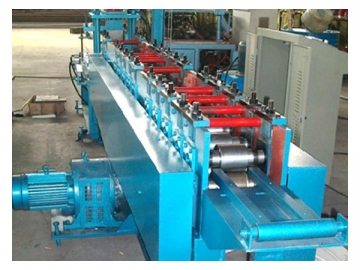

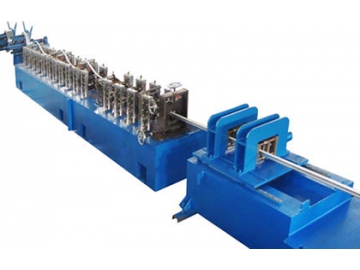

Steel Stud and Track Roll Forming Machine

The steel stud and track roll forming machine is used for cold roll forming of steel strips in a continuous process. It can produce a great selection of complicated metal profiles, such as lightweight steel studs, various architectural profiles, steel structures and highway guardrails, just to name a few. In addition, we also supply various types of cold bending machines and painting machines if needed.

Features of the Steel Stud and Track Roll Forming Machine

1. This rollformer machine is fully PLC controlled. It comes with multiple protective functions for safe production of studs and tracks.

2. The machine bed is made by welding of steel plates. It has been tempered to remove internal stress, thus preventing our steel framing equipment from unwanted deformation.

3. The roll forming unit is constructed from cast iron and has undergone tempering process in order to produce a combination of high mechanical strength and long service life.

4. The forming roll is made from 40Cr materials. It has been tempered to ensure a hardness of up to HB280.

5. The roll forming dies are formed by GCr15 materials. They are subjected to quenching process to ensure a hardness of HRC56-62.

6. Driven by a high-quality gearbox, this roll forming equipment can work under full load for a long time and delivers an ultra-long service life.

Parameters of the Steel Stud and Track Roll Forming Machine

| Roll Forming Capacity | Width: ≤150mm, Sheet Thickness: 0.6-2.0mm |

| Production Speed | 6-13m/min. |

| Total Power | Approximately 5.5kW |

| Production Area (L×W) | 15m ×2.5m |

Roll Forming Process: Decoiling → Straightening → Roll Forming → Cutting → Run-out Table

Components of the Studmaker Machine:

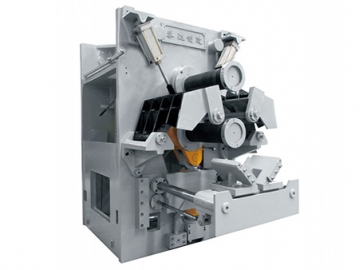

1. An uncoiler,

2. A guiding system,

3. A roll forming unit,

4. A straightening unit,

5. A cut-to-size system,

6. A run-out table,

7. And a control panel etc.