QT Cast Iron Submersible Sewage Pump

This product has been discontinued and removed from our shelves.

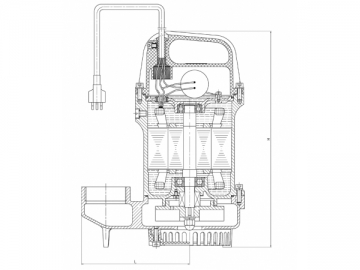

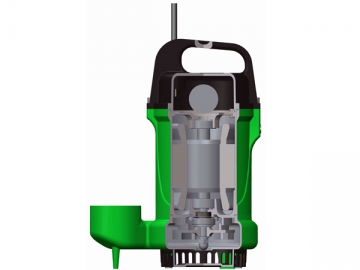

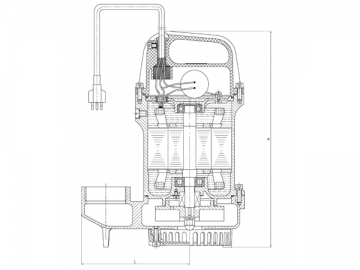

QT cast iron submersible sewage pump is composed of motor, water pump and sealing parts. The motor is single phase oil filled asynchronous type, and it is on the top end of entire machine. It is single phase capacitor driven, and has thermal protector. On the other hand, the water pump is set on the bottom end of entire machine, and it has a structure of vortex impeller-volute. Single mechanical seal works as the motive seal between motor and water pump, and oil resisting rubber O ring is used as the static seal for rabbet.

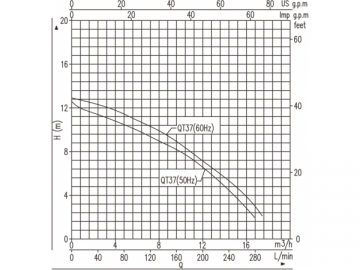

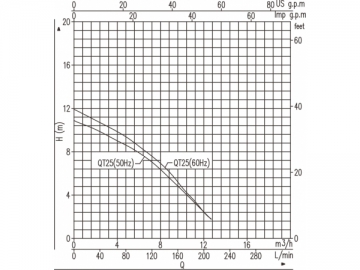

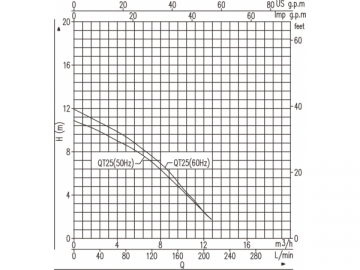

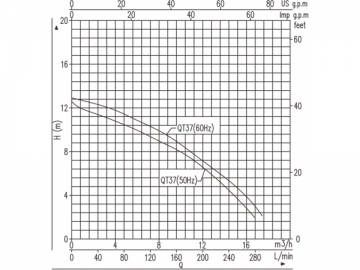

Performance Curve

QT25

QT37

| Model | Voltage (V) | Frequency (Hz) | Head (m) | Flow (m3/h) | Inner Diameter of Pipe (mm) | Max. Allowed Particle Diameter (mm) | Overall Dimension (L×W×H, mm) | Weight | |||||||||

| 0 | 2 | 4 | 6 | 8 | 10 | 12 | 14.5 | 16.5 | Gross Weight (kg) | Net Weight (kg) | |||||||

| QT25 | 220 | 50 | 10 | 9.3 | 8.2 | 6.8 | 5.1 | 1.5 | - | - | - | 51 | 7 | 230×160×310 | 12 | 11 | |

| 220 | 60 | ||||||||||||||||

| 120 | 60 | ||||||||||||||||

| QT37 | 220 | 50 | 12 | 10.5 | 10 | 9 | 8 | 7 | 6 | 4 | 2 | 13 | 12 | ||||

| 220 | 60 | ||||||||||||||||

| 120 | 60 | ||||||||||||||||

Note: n=2850r/min (50Hz), n=3450r/min (60Hz)

H=310mm, L=155mm, G2 pipe thread

Cast iron is used to produce machine casing, pump body as well as impeller, and the head cover and mesh enclosure are made of nylon plastic. Our product has some excellent properties including small volume, low noise, compact structure, high efficiency, stable running, convenient maintenance, beautiful appearance, easy transportation, outstanding energy saving ability, etc. It is suitable for the lifting and delivering of liquid with many impurities, such as mud, sand, short fiber, paper scrap, soft solid and other solid particles. So, the applicable liquid includes sewage, mud water, grey water, excrement, domestic wastewater, etc.

Based on the features above, this sewage pump is widely used in industry, agriculture, mine, building construction, environment protection and other places. For example, it is the perfect equipment for desilting of pool as well as irrigation and drainage of farmland. But, it can’t work if anti-explosion is required.

Materials

1. Machine casing: Cast iron

2. Pump body: Cast iron

3. Impeller: Cast iron

4. Upper bearing block: Aluminum

5. Shaft: 2Cr13

6. Head cover: Nylon (PA66G30)

7. Mesh enclosure: Nylon (PA66G30)

Working Conditions

1. Liquid temperature: ≤ 40℃

2. PH range of liquid: 4~10

3. Max. liquid density: 1.2×103kg/m3

4. Power supply frequency: 50Hz or 60Hz

5. Voltage: Single phase 220VAC or 120VAC, and the voltage fluctuation should be within ±10% of rated voltage.

6. Max. submersion depth: 5 meters

Motor

1. 2-pole motor

2. Single phase 220V(50Hz/60Hz), or 120V(60Hz)

3. Insulation class: B

4. Protection rating: IP68

Model Instruction

QT-25

25: 1/10 of the output power (W)

QT: Oil filled small submersible sewage pump

Maintenance

1. Please check the insulation resistance between winding and machine casing regularly, and this value must be higher than 1MΩ when the temperature is close to working temperature. Otherwise, corresponding measures must be applied to reach this value before use.

2. After the pump has worked normally for 2000 hours, the following steps should be carried out for maintenance. First, disassemble the machine and detect the expendable parts, such as impeller, rolling bearing, mechanical seal, etc. If any component is damaged, please replace it in time. Second, after the maintenance or replacement of sealing parts is finished, the pneumatic test for motor cavity should be executed, and the testing pressure is 0.2Mpa. Leakage and sweat phenomena should not take place for the initial 3 minutes. Finally, dismantle the refueling screw on the casing, and add 10# machine oil. If the machine is used for drinkable water, edible oil is also suitable.

3. When the machine will be idle for a long time, it is not appropriate to keep it in water. It should be placed in water and run for several minutes, and clean the coagulations in and out of the pump. Then, dry the machine, and anti-rust treatment should be done. At last, keep it in dry and ventilating place with care.

As a professional cast iron submersible sewage pump manufacturer and supplier in China, we also provide self-priming peripheral pump, self priming jet pump, submersible screw pump, and automatic exhaust circulator pump, among others.

Related Names: Iron Casting Submerged Sludge Tank Pump | Iron Casting under Water Sump Pump