Toast Moulder

Product Performance

The toast moulder is designed for making toast, Philippine bread and other kinds of roll-bread. Moreover, application for flattening dough is also available. The dough processed with this machine is completely free of bubble. The moisture in the dough can be well preserved.

1. Due to the oil-immersed design, the motor has good abrasion resistance and the noise caused during operation is low.

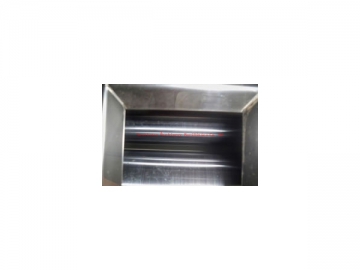

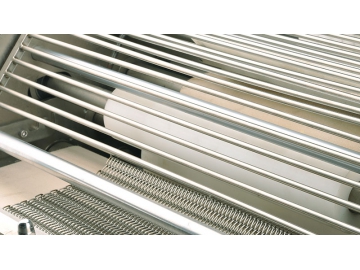

2. The surface of the roller is specially processed with hard chrome. Thus the roller is scratching-resistant and the flour on the dough will not stick to the roller.

3. The operation speed of the toast moulder is very fast. So, the air in the dough can be completely extruded. Additionally, the dough can be stretched to the maximum length. Since no pore is caused during processing, the toast produced has good structure.

4. The appearance of this machine is quite attractive. It can be used in the shopping mall, supermarket and the bakery.

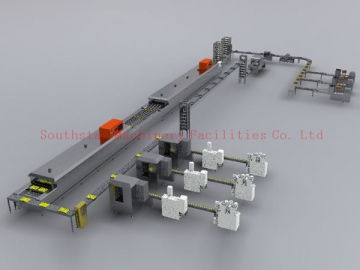

| Model | Rated Voltage (V) | Power (Kw) | Width (mm) | Net Weight (kg) | Dimension (mm) |

| 380/220 | 0.8/1.13 | 380 | 237 | 1400×670×1120 | |

| 380/220 | 0.8/1.13 | 380 | 200 | 900×700×1120 |

Product Characteristic

I. The machine is produced with special structure. So the dough can be well stretched. The complete extrusion of air makes for the good elasticity of the dough.

Three-time kneading

-

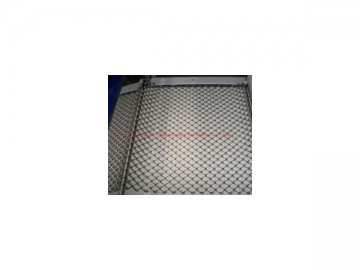

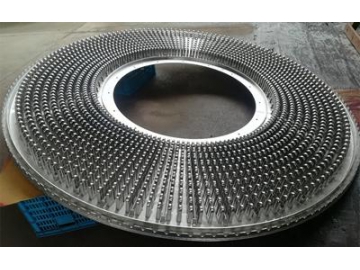

The dough will be pressed twice by the meshyrollers.

-

The air in the dough can be fully extruded after the dough is scrolled with the stainless steel meshy rollers. After kneading twice, this machine can make the dough into 2.5 to 3 rolls, which is 1 roll more than that is made by the common moulder.

-

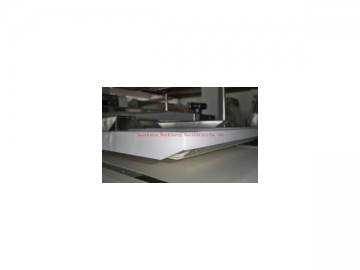

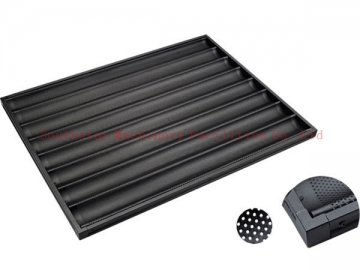

Themoulding plate will shape the dough into square.

-

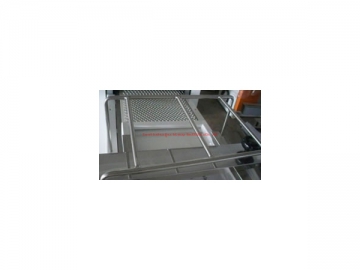

Durable conveyor belt

-

The rack above the conveyor belt is designed to place the necessary materials used in processing. It will save the space and bring convenience for you during operation.

-

The motor of the toast moulder is powerful to make for high working efficiency of the machine. Meanwhile, the thickness of the dough processed can be adjusted.

II. Only 3 seconds are required for each shaping. With the improved working efficiency and good moulding quality, the labor cost is greatly reduced.

Operating Instruction

I. The blue button is used to start the operation of the machine. Oppositely, the red one is the emergency stop button.

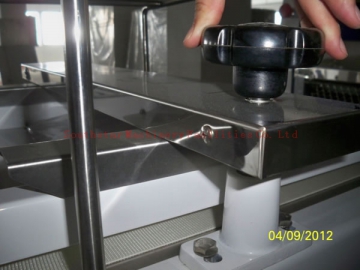

II. There aretwo small hand wheels on the top of the toast moulder designed to adjust the width of the inlet for dough. Adjust the dough inlet to the proper size needed and fasten the hand wheels before operating the machine. If the width set up is wider than that is required, the dough will extend to the outside of the rolling surface, which will lead to the waste of flour accordingly.

III. The other two big hand wheels are used to adjust the space between the rollers. The space between the rollers for first flattening shall be bigger than that of the rollers for second flattening. Flattening the dough twice with one single operation, the machine has a high working efficiency and can make the dough have good elasticity.

IV. The hand wheel can be used to adjust the height of the moulding plate on the arm. The specially-designed plastic plate with patterns is used to knead the dough. The height of the moulding plate shall be decided by the different shaping requirement. If the dough is processed for flattening only, the moulding plate of the toast moulder shall be lift up for spare.

V. There is a sliding plate designed at the outlet of the conveyer belt. This plate can be pulled out to pick the dough processed.

More Selections

If your bakery is not big enough, the NFZ-380A toast moulder is a good choice for you.

Packing for Delivery