KRHA Vacuum Mixer Homogenizer

A distinctive look and a powerful scraper make this vacuum mixer homogenizer a real eye-catcher. The rotor-stator homogenizer and scraper vanes are able to rise along with the lid of the mixing tank. Inclinable means the tank can be tilted for easy discharge of the mixture as well as for convenient repair and cleaning. All these desirable features are the result of our growing emphasis on the scientific research of high shear mixing technology.

Considering the different scales of production in diverse cosmetics companies, we have designed a total of 12 types of vacuum mixer homogenizer accordingly, available in volumes from 35L to 2500L.

Model KRHA is a high shear batch mixer of the choice when it comes to producing stable emulsions for mid and high-class cosmetics, ointments, and other emulsion-based beauty or pharmaceutical products. Based on previous sales experience and customer feedback, we now offer two popular versions: the standard vacuum mixer homogenizer and one that specifically designed for use in emulsion-based pharmaceutical industry.

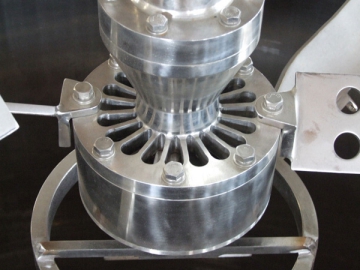

Main Parts

The vacuum mixer homogenizer comes with many parts as standard, including the emulsification tank (with a movable lid that can rise and lower its position, and a tank body that is able to be tilted), top-mounted high shear homogenizer, premix tank, vacuum system, heating and cooling system, and electrical enclosure.

Features of the Vacuum Mixer Homogenizer

1. Oil and water are sucked into the tank under vacuum conditions. This reduces the number of bubbles in the finished mixture, ensuring an ultra fine, flexible emulsion.

2. All product contact surfaces are made from SUS316L stainless steel for easy cleaning. Exposed steel surfaces are then polished and passivated to obtain a corrosion-resistant finish. Food grade mixer ensures maximum process hygiene.

3. This series of high shear mixer has been built to meet GMP standards. It offers choices of control modes, either with ordinary buttons or human-machine interface.

Technical Specifications of the Vacuum Mixer Homogenizer

| Type | Emulsification Tank Volume | Volume of Dissolving Pot (Premix Tank) | Dimension | Total Power | Weight |

| L | L | L×W×H mm | Kw | Kg | |

| 35 | 45/45 | 2500×2380×2190~2950 | 6.35 | 980 | |

| 50 | 45/50 | 2870×2390×2280~3000 | 7 | 1150 | |

| 100 | 75/100 | 2900×2600×2240~3060 | 8.6 | 1800 | |

| 150 | 100/150 | 3000×3000×2400~3300 | 10.3 | 2000 | |

| 200 | 125/185 | 3500×3100×2430~3630 | 11.8 | 2300 | |

| 300 | 185/330 | 3600×3200×2550~3670 | 14.2 | 2800 | |

| 350 | 250/378 | 3650×3250×2600~3780 | 14.2 | 3100 | |

| 500 | 330/480 | 3700×3360×2950~4220 | 22.4 | 3500 | |

| 600 | 330/600 | 3750×3380×3200~4600 | 22.4 | 4000 | |

| 750 | 480/750 | 4600×4250×3400~5000 | 28 | 4800 | |

| 1000 | 480/1030 | 4700×4360×3750~5350 | 33.8 | 6300 | |

| 2500 | 1200/2000 | 7120×4000×4892~6292 | 67.5 | 16000 |

Applications