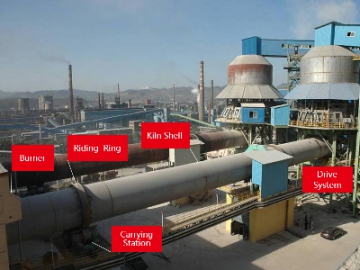

Cement Clinker Rotary Kiln

The cement clinker rotary kiln is the main equipment for cement clinkers calcining in chemical industry, metallurgy industry, etc. Through technological innovations, the calcination system of this cylindrical calcinator has been equipped with the most advanced hydraulic thrust roller in the world and various advanced devices in China, including highly accurate measuring plunger pump, greatly precise compensated flow control valve and contact-type graphite sealing device, etc.

In order to improve the degree of automation, an industrial television is mounted on the kiln head to check the calcining fire; a fluorescent screen is used to implement technical process analog; and an infrared scanner is equipped in the burning zone to directly reflect the calcining condition to the control computer. These new technologies contribute to the capability of directly observing the working condition, convenient operation and reliable application. In addition, in this cement clinker rotary kiln, the thermal regulation is stabilized and operation rate is improved. As compared with the same specification equipment, the operation rate of this cement clinker sintering furnace is increased by 3-5% and the output rises by 5-10%, while the heat consumption is reduced by15%.

Technical parameters List 1| Specifications(m) | Φ2.8/2.5×44 | Φ3.2×52 | Φ3×48 | Φ3.2×50 | Φ3.3×50 | Φ3.5×54 | Φ4×60 | Φ4.2×60 | ||

| Capacity (t/d) | 300 | 600 | 700 | 1000 | 1200 | 1500~1800 | 2500 | 3000 | ||

| Slope of kiln shell (%) | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | 3.5 | ||

| No. of supports | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Type of thrust roller | Mechanical | Mechanicalor hydraulic | Mechanicalor hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | ||

| Rotate speed of kiln | Main drive (r/min) | 0.445-2.22 | 0.676-3.38 | 0.676-3.38 | 0.36-3.57 | 0.36-3.57 | 0..39-3.9 | 0.41-4.07 | 0.4-4 | |

| Auxiliary drive (r/h) | 4.75 | 9.36 | 9.36 | 6.5 | 5.61 | 7.66 | 8.2 | 8.16 | ||

| Main drive | Motor | Rated power (kw) | 55 | 100 | 100 | 160 | 160 | 220 | 315 | 400 |

| Speed adjustable range(r/min) | ~1000 | ~1500 | ~1500 | ~1500 | ~1500 | ~1000 | ~1000 | 100~1000 | ||

| Rated voltage(V) | 440 | 440 | 440 | 440 | 440 | 440 | 440 | 440 | ||

| Reducer | Total ratio (%) | 49.63 | 49.63 | 49.63 | 40 | 40 | 28 | 22.4 | 31.5 | |

| Tachometer generator | Measurement range(r/min) | 0~2000 | 0~2000 | 0~2000 | 0~2000 | 0~2000 | 0~2000 | 0~2000 | 0~1000 | |

| Auxiliary Drive | Motor | Rated power(kw) | 4 | 7.5 | 7.5 | 15 | 11 | 18.5 | 22 | 30 |

| Speed adjustable range(r/min) | 1440 | 970 | 970 | 1460 | 1460 | 970 | 1470 | 1470 | ||

| Rated voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Reducer | Total ratio (%) | 40.44 | 14 | 14 | 31.5 | 31.5 | 45 | 45 | 45 | |

| Total weight (t) | 177 | 213 | 213 | 280.6 | 317 | 341 | 434 | 532 | ||

| Specifications(m) | Φ4.3×64 | Φ4.3×66 | Φ4.8×72 | Φ4.8×74 | Φ5×74 | Φ5.2×78 | Φ5.6×87 | Φ6×95 | ||

| Capacity (t/d) | 3500 | 3200 | 5350 | 5000 | 6000 | 6000 | 8000 | 10000 | ||

| Slope of kiln shell (%) | 4 | 4 | 3.5 | 4 | 4 | 4 | 4 | 4 | ||

| No. of supports | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Type of thrust roller | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | ||

| Rotate speed of kiln | Main drive (r/min) | 0.4-4.0 | 0.4-3.99 | 0.36-4.56 | 0.35-4 | 0.35-4 | 0.4-4 | max4.23 | max5 | |

| Auxiliary drive (r/h) | 7.93 | 9.9 | 8.65 | 8.52 | 7.58 | 8.76 | 8.7 | 9.2 | ||

| Main Drive | Motor | Rated power (kw) | 400 | 420 | 710 | 630 | 710 | 800 | 800 | 950×2 |

| Speed adjustable range (r/min) | 100~1000 | 1000 | 80~1000 | 1500 | 87.5~1000 | 100~1000 | 100~1000 | 100~1000 | ||

| Rated voltage (v) | 440 | 440 | 660 | 660 | 660 | 660 | 660 | 660 | ||

| Reducer | Total ratio (%) | 31.5 | 35.526 | 26.812 | 42.226 | 26.812 | 26.646 | 23.901 | 26.646 | |

| Tachometer generator | Measurement range(r/min) | 0~2000 | 0~2000 | 0~1000 | 0~2000 | 0~2000 | 0~2000 | 0~2000 | 0~2000 | |

| Auxiliary Drive | Motor | Rated power (kw) | 30 | 37 | 55 | 55 | 55 | 90 | 90 | 132 |

| Speed adjustable range (r/min) | 1470 | 1480 | 1480 | 1480 | 1480 | 1480 | 1480 | 1490 | ||

| Rated voltage (v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Reducer | Total ratio (%) | 45 | 35.745 | 46.844 | 28 | 45 | 35.795 | 35.795 | 35.795 | |

| Total weight (t) | 562 | 599 | 854 | 854 | 894 | 990 | 1201 | 1580 | ||