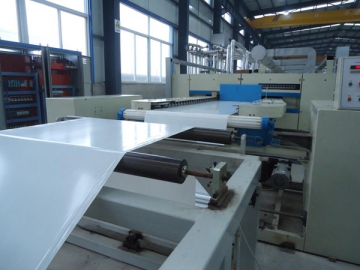

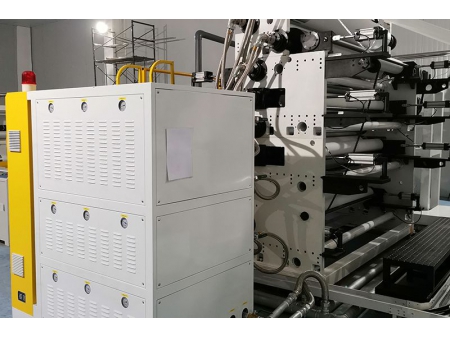

Waterproof Breathable Film Extrusion Line

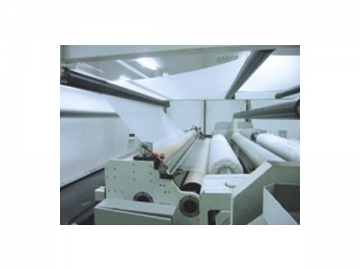

The breathable film allows air to circulate while keeping out moisture. More than 5 years of experience in researching and manufacturing the breathable film extrusion line allows us to gain advanced extrusion technologies. From the raw material plastification and casting to the final stretch forming, each process presents a challenge to HANDERN's expertise.

In comparison to other Chinese film extrusion lines, our extrusion equipment exhibits many unique advantages in configuration optimization, energy saving, and manufacturing and processing technologies. Overall performance tests show that each and every technical specification of our extrusion machine reaches internationally advanced level. As a matter of fact, HANDERN plastics extrusion line is among the fastest, most advanced Chinese equipment for producing breathable films.

The water vapor transmission rate of the resulting film from our plastics extrusion line, if measured at the temperature of 37℃ and relative humidity of 90%, is up to 8000g/m2(24h). As the state-of-the-art polymeric material, the breathable film has much higher processing technology requirements than ordinary water-proof materials. As far as material quality is concerned, the breathable film has far more desirable functionalities than other water-proof materials.

Applications

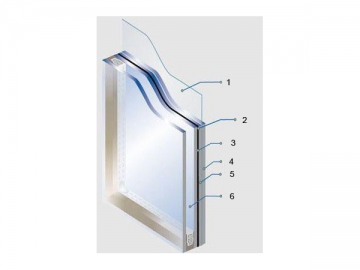

Personal hygiene products: tampons, baby diapers, green scrubs, disposable bed sheet

Daily necessities: raincoat, gloves, waterproof clothing

Building products: breathable materials, etc.

Technical Specifications

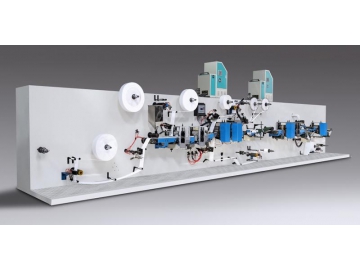

1. Breathable Film Width: 1200mm-2600mm

2. Linear Speed of the Extrusion Equipment: 100-180M/MIN

3. Breathable Film Thickness: 0.015mm-0.08mm

4. Maximum Production Capacity: 200-300-400-500-600KG/h