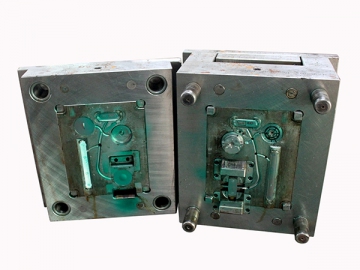

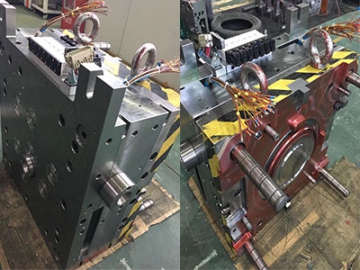

Highly Polished Injection Mould

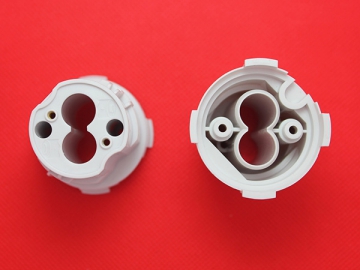

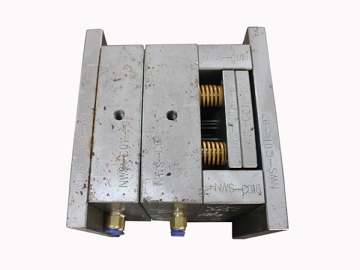

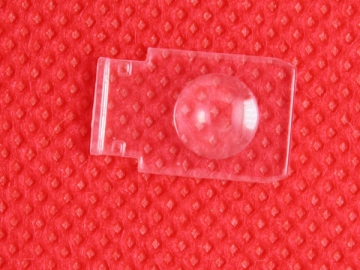

With a highly polished injection mold, it becomes possible for you to produce high-precision housings for your electronic products. Developers at A&R Technology pick up S136 steel and use it in place of conventional 2316 steel to make our highly polished mold which later proves to sturdier and more corrosion-resistant. Performing injection molding in such a high-quality mold allows you to control the dimensional accuracy of molded parts. The corrosion resistant property also gives the mold a smooth internal surface which makes it possible to produce highly-polished parts.

Once the final mold shape is formed, polishing treatment is required to impart a smooth finish to the mold. Having an outside dimension set at 650mm×650mm×550mm, this injection mold features a small sprue and cold runners design which enables the production of more precise products. After the electronic housing is produced, the sprue and cold runners will be separated from the main mold cavity automatically. The 4 side channels direct the resin flow into 4 mold cavities, resulting in 4 finished products of the same shape.

This injection mold works perfectly for ABS or polycarbonate materials. It can be used half a million times before being discarded. Thus a significant amount of investment in molds can be saved. While we do have a product catalog, most of our molds are custom made to reflect clients’ need 100%. Give us your specifications or design drawings and we can customize your mold accordingly. Though our mold is simple to install and easy to use, please do feel free to contact us when you have issues with our products during operation.