Flux Regenerating Equipment

Flux regenerating equipment for galvanizing equipment

The GD-PIRE flux regenerating equipment is an advanced auxiliary equipment for galvanizing. It has been widely used for the pretreatment of steel wire, steel tube, and structural steel, because it can effectively remove the ferrous ion from the flux solution and improve the galvanization performance.

Our GD-PIRE flux regenerating equipment uses strong oxidant to oxidize the ferrous ion to ferric ion. Then AC value of the solution will be adjusted to make the ferric ion become a kind of sediment,Fe(OH)3. The impurities and sediment will be removed by a mechanical filter. An electric control system is available for the addition of reagent A and B, ensuring that the ferrous ion in the solution stays at a low level (below 1g/L).

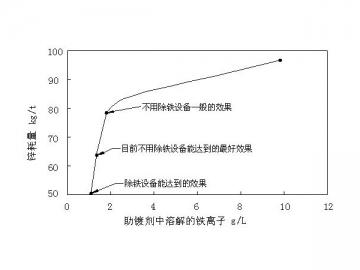

In practice, when the ferrous ion concentration is below 1g/L, the zinc consumption can be effectively reduced (4%), while the alluminium and nickel consumption is also lower. Besides, the mobility of molten zinc also gets better, leading to better workpiece surface. So using our GD-PIRE flux regenerating equipment, the galvanization will become more eco-friendly and energy saving, the product quality also becomes better.

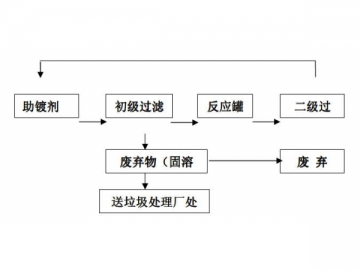

Component of the flux regenerating equipment for galvanizing equipment

As shown in the Fig. 1, this kind of equipment comprises electric control system, reaction system, and filtering system.

1. Electric control system

A PLC device from Japanese Mitsubishi is adopted for the control system, and the interface is quite user-friendly. This system is can adjust the addition of reagent A and B by monitoring the flow rate in the pipe realtimely. Thus the flux regenerating equipment can work efficiently withour human operation.

2. Reaction system

The ferrous ion in the solution will be oxidized into ferric ion by the reaction system. The entire reacting process is completed in a mixing device, ensuring that the the chemicals are fully reacted. The pipeline is made of PP material which is corrosion resistant and high temperature resistant. So the flux regenerating equipment can work stably for a long time.

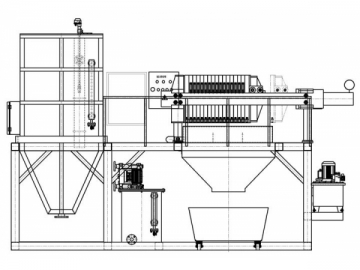

3. Filtering system

The sediment generated during the reaction will be kept in the filtering device. Thus the solution bath can keep clean, and the production can carry on stably. The filter system features easy cleaning process, great durability, anti-aging performance, and long service life.

Feature of our flux regenerating equipment

1. This kind of equipment has a high automation degree. It can precisely control the chemical reaction, filtering process, and impurity removing. Thus the entire regeneration proess is quite accurate, fluent and efficient. This zinc plating equipment is manufactured on the basis of adequate experiments. The mathematic models have been developed. Besides, we also purchased advanced sensors and software for the precise control of the regenerating process.

2. The on-line working process won’t reduce the efficiency of the whole galvanizing process.

3. Our equipment features compact structure, high operational efficiency, small floor occupation, and stable working performance.

Technical parameter of the flux regenerating equipment

Processing capacity: 1~5m3/h

Ferrous ion concentration: lower than 1g/L

Installed power: 10kW

Control device: PLC

Floor occupation: 5×3m

Economical efficiency

Production cost

To reduce the ferrous ion concentration of 5 m3 flux solution from 10g/L to less than 1g/L, we need 60Kg strong oxidant (30%, w/w) and 182 Kg neutralizer (25%, w/w).

Economic benefit

1. The product quality can be greatly enhanced, because less ferrous ion in the melted zinc leads to higher mobility of the zinc. Then the plating layer’s smoothness and brightness can be improved.

2. According to the statistics from our clients from Europe, the United States, and Korea, the zinc consumption is lowered by 0.466-1.007%, and the average number is 0.737%. For a company with a production capacity of 30,000 tons, our equipment can save about 220 tons of zinc each year.

3. When two kinds of additives are added, the generated ammonium chloride can reduce your ammonium chloride consumption in the flux solution. If a special acid rinsing bath for unqualified galvanized parts and hanging tools is available on the galvanizing line, our flux regenerating equipment can be also used for regenerating zinc chloride solution with ferrous iron. The regenerated solution, as a zinc chloride supplementary, can be added to the flux solution bath, saving you more cost.

The relationship between ferrous ion content in flux solution and the zinc consumption- Zinc consumption kg/t

- Regular performance without flux regenerating equipment

- Best performance without flux regenerating equipment

- Performance using our flux regenerating equipment

- Ferrous ion in the flux solution g/L

- Flux solution

- Preliminary filtering

- Reaction tank

- Secondary filtering

- Waste (solid matter)

- Discarding

- Waste treatment plant