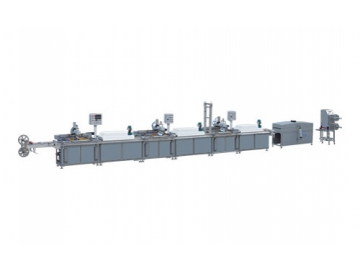

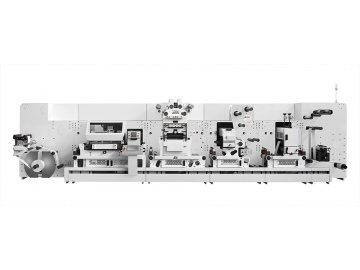

Automatic Screen Printing Machine

Features

We adopt the classic stop-cylinder mechanism to our JB-A series automatic stop-cylinder screen printing machine, featuring high speed, low noise, high precision printing, high degree of automation, accurate and stable positioning of paper, etc.

Our automatic screen printing press can be excellently applied to all kinds of industries, including ceramics and glass paper, advertising, packaging, printing, signage, textile transfer, electronics, such as the membrane switch, flexible circuit, instrument panels, mobile phones, etc.

- Paper Feeding Mechanism

- Push-Pull Register

- Self-Lubrication

- Pneumatic Pressure Maintaining Device

| Models | | | |

| Maximum paper size | 720mm ×520mm | 800mm ×610mm | 1,020mm ×720mm |

| Minimum paper size | 350mm ×270mm | 350mm ×270mm | 560mm ×350mm |

| Maximum printing area | 720mm ×500mm | 800mm ×600mm | 1,020mm ×710mm |

| Paper thickness | 108mm -400mm | 108mm -400mm | 120mm -400mm |

| Seaming white edge | ≤10mm | ≤10mm | ≤10mm |

| Printing speed | 1,000-3,600 Pieces/ Hour | 1,000-3,300 Pieces/ Hour | 1,000-3,000 Pieces/ Hour |

| Installed power | 3p 380v 50Hz 8.89KW | 3p 380v 50Hz 8.89KW | 3p 380v 50Hz 14.64KW |

| Total weight | 3,500kg | 4,000kg | 5,000kg |

| Dimension | 4,050mm ×2,240mm×1,680mm | 4,350mm ×2,580mm×1,680mm | 4,650mm ×2,800mm×1,680mm |

Features

1. Our automatic stop-cylinder screen printing machine's classic stop-cylinder mechanism has cylinder stop automatically to correctly guarantee the printing stock is sent to the gripper, achieving high accuracy; meanwhile, the gripper and the push-pull register are both equipped with magic eyes to monitor if the printing stock is in place, effectively reducing the rejection rate of printing.

2. This screen printing equipment has push and press mechanism and the vacuum adsorption structure at the bottom of the paper feeding workbench, which can ensure the accurate and smooth transport of various printing materials.

3. The two cams control the movement of the squeegee and the ink knife; the squeegee is equipped with the pneumatic pressure maintaining device, generating clearer printing image and more uniform ink layer.

4. The screen frame of our automatic stop-cylinder screen printing machine can be pulled out for the adjustment of register or paper feeding. Moreover, the cleaning of the cylinder and screen is safer and faster. Meanwhile, there is an ink tray device to prevent the ink from dripping on the roller.

5. The main transmission and major components can realize self lubrication, effectively increasing the precision and extending the life service of our screen printing machine.

6. Being in the centralized control of the PLC, our automaticstop-cylinder screen printing machine has high degree of automation, as well as the user-friendly dual operating system of touch screen and button.

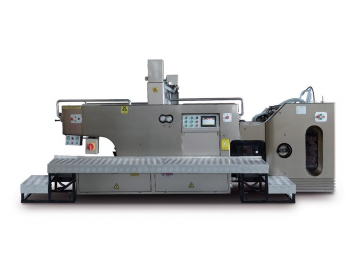

7. Ourautomatic screen printer for sale can be used with PRY series screen drying machine, UV curing machine/ UV& IR drying tunnel and automatic paper collecting machine, forming the full automatic printing production line.

Application Range of Automatic Screen Printing Machine