Batch Asphalt Mixing Plant

- LB-1000 type (can be relocated) intermittent mandatory automatic asphalt mixing equipment

- LB-1500 type (can be relocated) intermittent mandatory automatic asphalt mixing equipment

- LB-2000 type (can be relocated) intermittent mandatory automatic asphalt mixing equipment

- LB-2500 type (can be relocated) intermittent mandatory automatic asphalt mixing equipment

- LB-4000 type (can be relocated) intermittent mandatory automatic asphalt mixing equipment

As a specific type of road construction equipment, the LB series asphalt mixing plant is specially designed for the construction of expressways. The modular structure of the mixing section is completely concealed, making the appearance appealing. The noise and pollution levels are also both reduced. Monitoring devices are mounted for the main working areas. This allows labor intensity and safety risk to be greatly reduced, and improves the working environment.

The automatic control system, full process monitoring system and automatic weighing system make the batch asphalt mixing plant highly accurate, safe and reliable.

In addition to the different types of roads, this asphalt plant can also be used for the construction of airports and dams, among other things. We provide a life-time of technical support for our products. If you need an upgrade solution, please contact us for a selection of related technologies such as heat recovery, asphalt modification, dust collection and more.

Modular design

The modular design and rapid installation technologies used in the batch asphalt mixer can make the transportation and equipment installation more convenient.

Stable and reliable performance

1. This batch asphalt mixing plant is designed by our international experts according to European standards. The electro-mechanical equipment is made of components imported from internationally known brands, which ensures the stability and reliability of our products. The PLC and professional computer controller are used in the control system which can automatically, semi-automatically or manually control the weighing, mixing, material feeding and other processes.

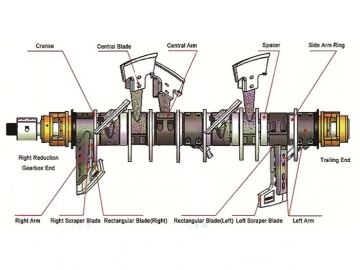

2. The scale board, arm, and blades in the mixing barrel of the batch asphalt mixing plant are all made of a high-temperature, wear-resistant casting iron, and each has a long service life. The aggregate, mineral powder and asphalt are all measured separately, in order to ensure the final material's ratio is precise. A double bucket chain elevator is used for the hot aggregate and mineral powder.

Various options

We have developed light oil, heavy oil, and coal burners for the batch asphalt mixing plant. The dust removal system comes either a cyclone dust collector in its first stage, and the second stage has a water or static bag dust collection device.

| Model | |||||

| Feature | Modular design, easy assembly and disassembly, intermittent production, computer operated | ||||

| Production capacity | 60 ~ 80 ton/h | 90 ~ 120 ton/h | 120 ~ 160 ton/h | 150 ~ 200 ton/h | 320 ton/h |

| Mixing capacity | 1000kg/batch | 1500kg/batch | 2000kg/batch | 2500kg/batch | |

| Working voltage | 380V/220V, 50Hz | ||||

| Operation | Automatic/semi-automatic/Manual/Computer controlled | ||||