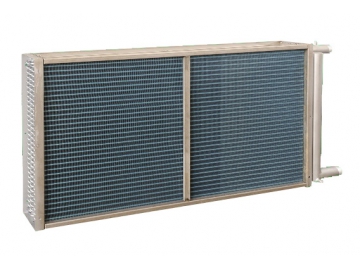

Evaporative Cooler Parts

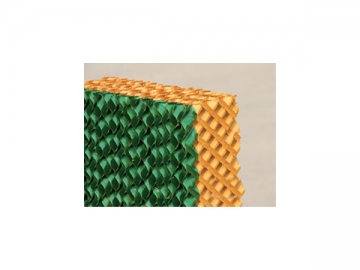

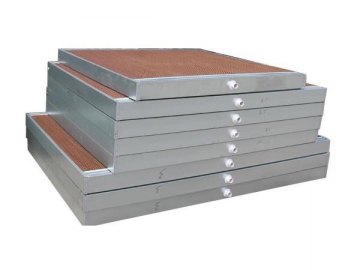

Our evaporative cooler pad has a honeycomb structure paper material that is used to cool air by using water evaporation processes that absorb heat in the ambient environment.

Evaporative Cooling Process

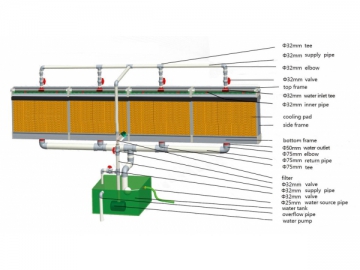

1. Water flows downwards into the corrugated paper pad to form a water film on the pad.

2. Hot dry air is sucked in by the draft fan and passes through the evaporative cooler pad

3. Water on the pad will absorb the hot air, removing large amounts of heat through evaporation.

4. The hot dry air is then cool and wet after going through the evaporative cooling pad, lowering the temperature in your room.

To what degree the temperature can be lowered depends on the difference between the dry bulb temperature and the wet bulb temperature, as well as the current working efficiency of the cooling pad. The cooling value is product of those. The cooling efficiency of a normal working evaporative cooler pad is usually constant, and the swamp cooler pad provides a great cooling effect during a hot summer.

Our evaporative cooler pad works together with a negative pressure fan to form a humidification cooling system. This system is eco-friendly and features a wide range of applications.

The evaporative cooling system we developed allows you to adjust the air speed and air output according to your practical environmental conditions. It can be widely used in greenhouses, enclosed pastures, textile workshops, garment making, injection molding, hardware factories, shoe factories, and other places where the temperature is high and ventilation conditions are poor.

As a professional evaporative cooler part manufacturer, our company is able to customize humidity and temperature control systems suitable for your specific environment.