Fiberglass Reinforced Roofing Sheet

- Fiberglass Reinforced Roofing Sheet Red

- Fiberglass Reinforced Roofing Sheet Blue

Jieli has served the plastic roofing industry for 20 years, providing a wide range of roofing supplies to the industry. One of those supplies is the fiberglass reinforced roofing sheet, which is one of our typical product lines. The FRP or GRP roofing sheet offers an incomparable combination of strength and corrosion resistance. Specifically, it is designed with four layers that are each constructed using one-step co-extrusion technology, which ensures great tenacity, fire resistance and mechanical strength.

With a higher reinforcing content, superior resin systems and extensive UV protection, this roofing sheet is ideal for challenging and tough conditions. It is widely used in industrial workshops, warehouses, market sheds, residences and more. This building material is also suitable for workshops that are exposed to acid, alkali and corrosive gases.

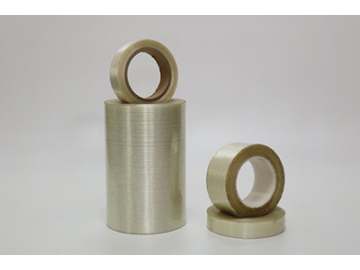

Materials and Structure

First layer material: ASA or PMMA

Second and fourth layer material: UPVC

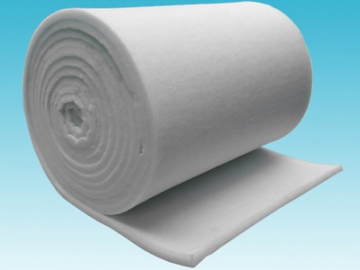

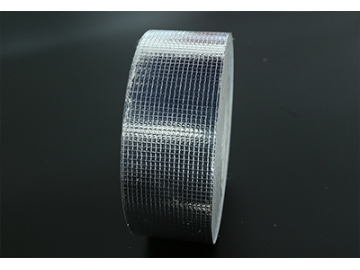

Third layer material: Fiberglass reinforced fabric

Product Features of FRP Roofing Sheet

- Premium Material and Lasting Color

We use weather proof engineering resins imported from France for the raw materials of our fiberglass plastic roofing sheets. These have excellent resistance to harsh weather and can maintain a long lasting beautiful color.

- Patented Technology

Jieli owns patented technology for manufacturing fiberglass reinforced roofing sheets (Utility Model Patent No.: 733091). We have creatively added a layer of strong glass fibers into two UPVC layers, effectively handling water penetration problems of chemical building materials caused by thermal damage.

- Great Corrosion Resistance

With the stable molecular structure, this plastic roof sheet can resist corrosions from acid, alkali, salt and other chemical substances for long periods of time. They are widely used in leather workshops, chemical workshops, aquaculture and seaside buildings.

- Impact Resistance

This roofing sheet comes with over 50% higher impact resistance than ordinary plastic roofing tiles. Therefore, it is harder to break, even after exposure to strong shocks, which improves the safety of the building and people.

Practice Proven Long Service Life

This roofing material has been exported to numerous countries all over the world. This fiberglass reinforced roofing sheet have been proven to serve at least 13 years, though in theory they can serve for more than 50 years.

Raw Material Superiority

Due to high quality raw materials, Jieli's GRP roofing sheets come with a relatively compact structure, avoiding wear problems such as water absorption and penetration.

Shape Superiority

This roofing sheet boasts a large effective width, which means there are fewer joints. This improves the water resistance of the roof.

Small Deformation

Using a glass fiber reinforced plastic as the main frame, the roof sheet can handle frequent deformation problems at the tack holes and joints caused by thermal changes, another way it prevents water leakages.

Specialized Accessories

All accessories for jointing and fixing purposes feature scientific waterproof design.

Premium Coating

The fiberglass reinforced roofing sheet is coated with a layer of PMMA or ASA materials, which enables a long lasting color.

Optional Colors

The roofing sheet is available in more than 10 different colors. According to customer requirements, colors can also be customized.

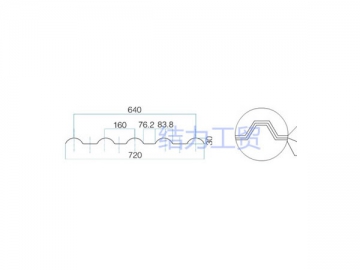

Optional Sizes

Jieli offers a wide range of fiber glass reinforced plastic roofing sheets in a multitude of sizes. Its width ranges from 640mm to 1,130 mm, and the thickness ranges from 2 to 3 mm. Customers can also choose from these specifications according to their needs.

Wide Application Range

The plastic roofing sheet is ideal for different types of roofs. It can be used on villas, workshops, pitched roofs, seaside buildings, and market sheds.

Easy Installation

This roofing product has an outstanding bending resistance that has been improved by 75%, and the purlin distances is 1/3 larger than PVC roof tiles, saving construction costs and improving roofing efficiency.

Technical Parameters

| Picture |  | |

| Material | Premium UPVC | |

| Basic structure | Fiberglass reinforce plastic roofing sheet | |

| Specifications | Wave | Trapezoid |

| Width | W720, W104 | W840,W880,w1088,w1130 |

| Thickness | 2mm, 2.5mm, 3mm | 2mm, 2.5mm, 3mm |

| Length | 3M or customized | |

| Colors | It can be customized | |

| Fireproofing grade | B1 | |

| Applicable structure | Concrete, wood, steel, brick-concrete, reinforced concrete | |

| Installation method | hanging | |

Applications

1. Workshops

2. Residences

3. Garages

4. DIY roofing sheet

5. Makeshift house roofing sheet

Specifications

Model: T940 Fiberglass Reinforced Plastic Roofing Sheet

Width: 940mm

Length: Optional

Thickness: 2.0mm, 2.5mm, 3.0mm

Colors: brick-red, red, blue, grey, green, black, white (color is also customized as per customer's requirements)