Magnetic Separator (Roller Type Separator for Chip Removal)

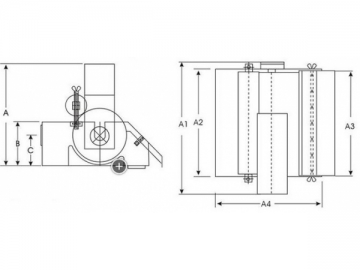

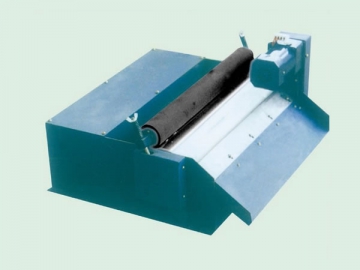

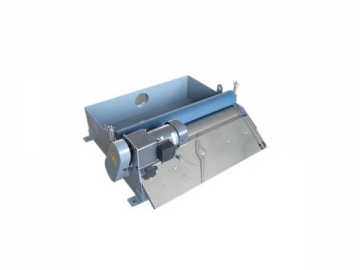

Magnetic separator is a roller type separator designed to remove chips. The magnetic rollers, driven by the reducer, rotate at high speed and attract the chips in the coolants. At the same time, chips stuck on the roller will be squeezed and scraped away from the roller by the scarping plate while the liquid will come out.

Functions of Magnetic Separator

1. It could effectively reduce the revisions of grinding wheels, promote the surface smoothness of workpiece and extend the lifespan of grinding wheels and coolants.

2. It not only mitigates the labor intensity but also decrease the pollution caused by coolants. Usually, this magnetic roller separator is matched with the paper filter to have higher filtration accuracy.

Applications of Magnetic Separator

Given the above fact, this separator has become an ideal auxiliary device for the grinding machines and automatic processing lines in industrial productions. Now, there are two types of magnetic separators available now, which respectively adopt the ferrites and NdFeB. The magnetic flux density of the former is 1000Gs, the latter’s is about 3000 to 5500Gs.

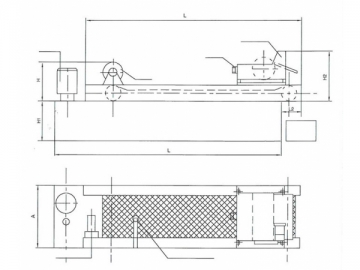

| Model | Main Parameters | Assistive parameters | |||||||

| Flow Rate L/min | Water inlet 01 | Water outlet 02 | Width A | Length B | Height H | Height of water inlet (H1) | Overall height (H2) | Motor Power(W) | |

| 25 | G2 | 80x100 | 320 | 200 | 190 | 115 | 320 | 40 | |

| 50 | G2 | 80x150 | 320 | 320 | 190 | 115 | 320 | 60 | |

| 75 | G2 | 80x200 | 320 | 380 | 190 | 115 | 320 | 60 | |

| 100 | G2 | 100x200 | 320 | 450 | 190 | 115 | 320 | 90 | |

| 150 | G2 | 100x250 | 320 | 510 | 190 | 115 | 320 | 90 | |

| 200 | G2 | 100x300 | 320 | 570 | 190 | 115 | 320 | 90 | |

| 250 | G3 | 120x200 | 550 | 450 | 190 | 115 | 320 | 120 | |

| 300 | G3 | 120x300 | 550 | 570 | 190 | 115 | 320 | 120 | |

| 400 | G3 | 100x350 | 550 | 700 | 240 | 160 | 450 | 120 | |

| 500 | 100x450 | 550 | 850 | 240 | 450 | 120 | |||

| 600 | 100x550 | 550 | 950 | 240 | 450 | 180 | |||

| 800 | 100x700 | 550 | 1100 | 240 | 450 | 180 | |||

| 1000 | 150x700 | 650 | 1200 | 400 | 720 | 250 | |||

| 1200 | or the upper inlet | 150x900 | 650 | 1500 | 400 | 720 | 250 | ||

| 1500 | 150x1100 | 650 | 1800 | 400 | 720 | 250 | |||

| 2000 | 800 | 1200 | 550 | ||||||

| 2500 | 800 | 1600 | 550 | ||||||

| 3000 | 800 | 1800 | 550 | ||||||

| X | |||||||||

Note

1. The water inlet could be mounted at the side, rear and upside of the device. The outlet could be at the lower or side part(better at the lower part if the water flow is large). The inlet and outlet could be mounted depending on customers’ requirements.

2. As for a long-time suspension, users need to clean the tank regularly to remove sundries;

3. The work flow need be set according to the nominal data or the overly large flow will impair the separation accuracy;

3. Chips(not powders), especially the steel chips will accelerate the abrasion of rollers and reduce the separator’s lifespan;

4. If the amount of chips to be filtered rises suddenly, users need to adjust the interval between the roller and the outer wall of magnetic drum, or the absorption amount of the wall will increase sharply and the roller can pass thorough the rolling area(where the absorbed chips to be squeezed).