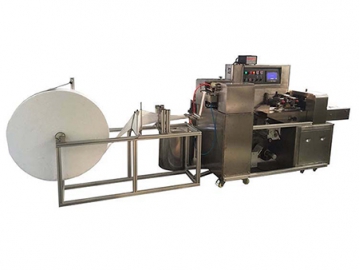

Single Sheet Wet Wipe Machine (Automatic Wet Wipe Folding and Packing Machine)

Customize people's favorite wet tissues!

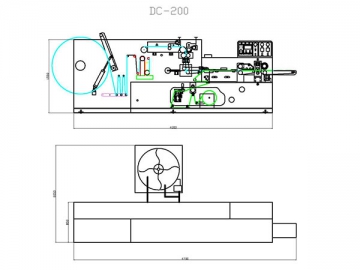

Manufactured according to CE standards, the single sheet wet wipe machine is an automatic wet wipe folding and packing machine, providing user friendly features and easy maintenance. Built with a steel structure, stainless steel plate, and stainless steel parts, the entire wet wipe machine is compact and solid. The major mechanical components are made using CNC machining centers, and important electrical components are from Siemens, Schneider, and other well-known brands.

By using this non-woven converting machine and using spun-laced non-woven fabric or airlaid paper as the raw materials, you can make wet wipes with different specifications, for different uses.

Unfolded size(mm): (160-260)×(150-200)(L×W)

Folded size(mm): (80-130)×(50-80)(L×W)

Folding type: "Z", "W"

Packaging film: PE & PET, OPP & PE (aluminum film)

Flexible Adjustment

1. The non-woven cutting length is adjustable.

2. The lotion supplying system includes a continuous mixing system and a recycling unity. The lotion applicator sucks liquid from the tank and sprays the liquid onto the product continuously, with an adjustable amount per action.

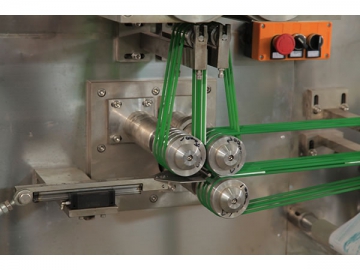

3. Products are conveyed using an imported conveyor belt. The friction coefficient can be adjusted to suit different conveying speeds, to ensure the whole wet wipe production line works at the highest efficiency.

4. Package forming: The length and width of the package can be adjusted by changing the forming unit.

Safety Protection

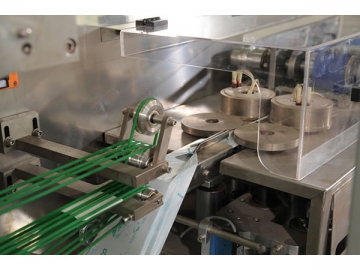

Taking operator safety into mind, the automatic wet wipe machine is outfitted with a protective system and emergency braking system. It also comes equipped with a security door made of Plexiglas and safe blades.

Automatic Production and Systematic Control

1. Human to machine interface, PLC control, monitoring system

2. Automatic operation, one person can control the entire machine.

3. Temperature auto control: each unit has an individual digital temperature indicator. The wet wipe machine can automatically adjust the temperature as it is set for the electrical thermo parts

4. Electrical control system: It consists of the main circuit system, second circuit control system, temperature control system, tension control system, PCL system, and other auxiliary parts.

5. Other systems include the sachet center sealing system, a code marking system, and the conveying system.

6. Transmission, rear drive belt

7. The phase is adjusted to be in sync with the machine’s running process.

8. The tension of the packaging film is controlled by the system.

Dachang is a leading wet wipe machine supplier with 16 years of experience. To meet different efficiency requirements, we provide two different models of automatic wet wipe folding and packing machines: DC-200A and DC-200B, with working speeds of 150-200 pieces/minute and 150-250 pieces/minute respectively. With excellent quality, the single sheet wet wipe machine features a high production speed and operational stability. In addition, the operation can be carried out in only a few simple steps. The wet tissue machines are popular among paper providers, daily goods manufacturers and hygienic product companies. Heng’an Group, a well-known paper products supplier in China, uses our single sheet wet wipe machine to produce their “Mind Act Upon Mind” brand of wet tissues. The machines have been running great for more than 10 years, and those that began to be used back in 2004 are still used in the production process today. The single sheet wet-wipe machine can make disinfectant wipes, cosmetic tissues and cleaning wipes.

Details- PLC Control

- Conveying Wet Tissues One-by-One

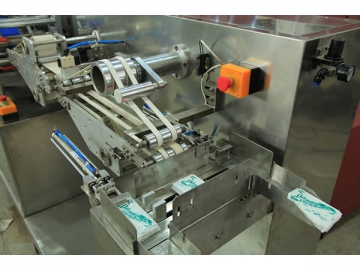

- Automatic Packing

- Finished Products