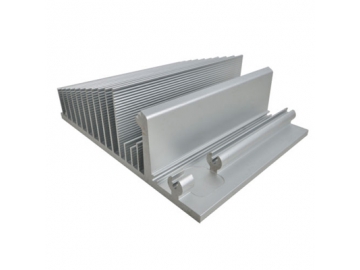

Aluminum Extrusion

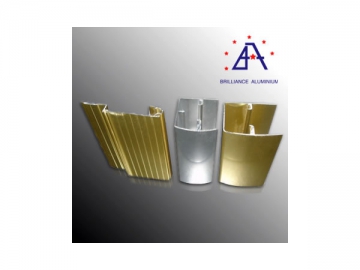

As a professional aluminum profile manufacturer, Brilliance offers multiple types of premium extrusions for customers. Our aluminum profiles and semi-manufactured components have gone through strict processes including polishing, brushing, electrophoresis, anodizing, powder coating, and finishing.

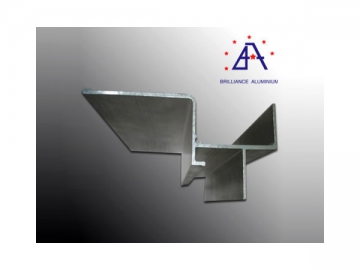

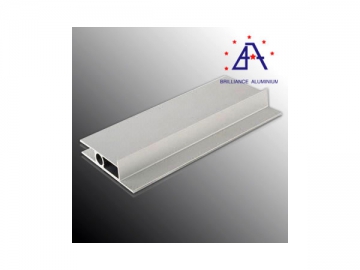

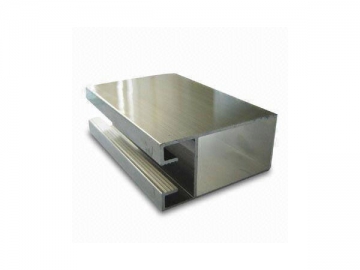

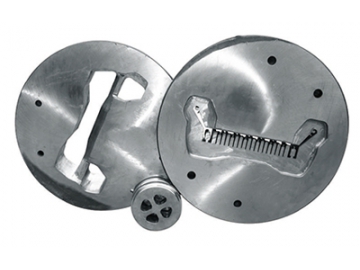

Available Types

Designed to meet customer's needs for performance, quality, precision and economy, our extruded profiles come with multiple standard types and various wood colors. We have over 1,000 different types of profiles in the product catalogue, including the following.

Along with the listed types, we can also produce customized extrusions depending on specific customer needs.

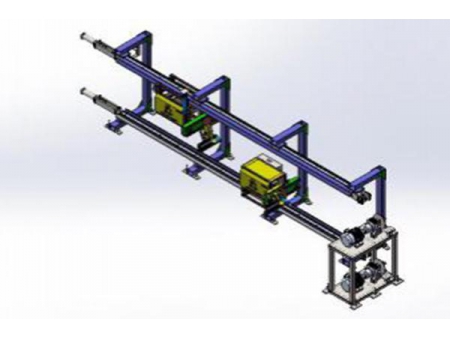

Applications of Aluminum Extrusion

An aluminum extrusion profile is a simple solution to almost all design problems. Made from quality aluminum instead of steel, wood or plastic, the extrusion can be found in almost every industry and is commonly used for a wide range of applications, including construction, automobiles, aviation, ships, factories, machines, and power stations.

Advantages of the Extrusion Process

1. The extrusion process allows the aluminum products to be freely shaped.

2. As the anodized aluminum extrusion needs fewer components and requires far fewer efforts in the fabrication and assembly, the production cost of the profile is lower than other products.

Compared to other materials and processes, it also has the following features:

a. Complex integral shapes

b. Cost effective

c. Low tooling costs

d. Design flexibility

e. Versatility in joining

f. Machinable

g. Rapid prototyping

h. Short lead times

i. Wide range of finishes