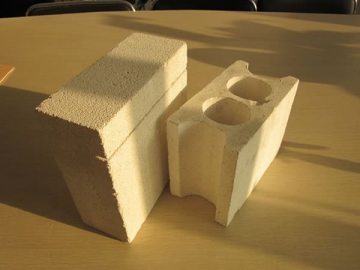

Silicon Carbide Brick

The silicon carbide brick possesses excellent high-temperature resistance, extremely high strength, satisfactory thermal conductivity and great shock resistance, well applicable for high-temperature indirect heating materials, such as vertical distillation furnace, rectifying furnace tray, aluminum reduction cell, lining of copper melting furnace, zinc powder furnace arc plate, thermocouple protection tube, etc.

Thanks to its great corrosion resistance, thermal shock resistance and wear resistance, the refractory brick can be used to make lining of large-scale blast furnace, significantly improving its service life. Due to its great thermal radiation and high-temperature strength, the silicon carbide can also be applied to produce sheet-type kiln furniture. This refractory material is excellent in decreasing kiln furniture volume, improving kiln’s capacity and product quality, and shortening production cycle. Besides, the silicon carbide is an ideal indirect material for calcining and sintering ceramic glaze.

Thanks to its great hardness (only inferior to diamond) and excellent wear resistance, the silicon carbide is ideal for abrasion resistant tube, impeller, pump chamber, hydrocyclone, ore bucket lining, airport runway and other silicon carbide products. Its service life is 5-20 times of cast iron and rubber.

Technical Indicators of Silicon Carbide Brick

| Indicators | Si3N4-SiC | Si2ON2-SiC | Sialon-SiC |

| SiC, (%) ≥ | 72 | 72 | 72 |

| Si3N4, (%) ≥ | 25 | 20 | 25 |

| Free Si, (%)≤ | 0.4 | ||

| Refractoriness under load 0.2 Mpa (℃ ) ≥ | 1750 | 1650 | 1750 |

| Apparent porosity (%) ≤ | 15 | 18 | 14 |

| Cold crushing strength (Mpa) ≥ | 150 | 150 | 150 |

| Fracture resistance at high temperature (Mpa) (1400℃ *0.5h) ≥ | 45 | 30 | 55 |

| Cold Fracture resistance (Mpa) ≥ | 50 | 30 | 45 |

| Thermal shock resistance (times) (1100 ℃ -water cooling) | 40 | 40 | 40 |