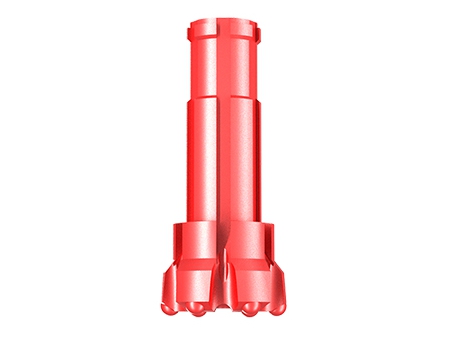

DTH Hammers

Down-the-hole drilling

At Starockdrill, every DTH hammer we produce combines state-of-the-art technology and craftsmanship with the highest quality materials available in the market. Our precision machining and heat treatment processes guarantee outstanding wear resistance and extended product lifespan.

Each DTH hammer undergoes rigorous testing and optimization by our team to meet the highest standards of performance and reliability. Our strict quality control and inspection procedures ensure that every component adheres to our precise specifications and norms.

Our DTH hammers support a wide range of popular drill bit shank designs used internationally. We also offer our proprietary STR series shank design that can be used with all common adapters. The API REG thread connection is commonly used for thread connections.

Our DTH hammers feature a variety of shank designs such as CIR, BR, DHD, COP, SD, MISSION, NUMA, MACH, and STR, catering to different hole sizes and specifications ranging from 1 inch to 33 inches.

The DTH hammers are suitable for drilling holes ranging from 64 to 1200 millimeters in diameter. Depending on the output power of your air compressor, we offer three types of hammers for you to choose from, allowing you to select the most suitable hammer to ensure optimal drilling efficiency and results:

- Low Air Pressure (0.5-0.7 cubic meters/minute)

- Medium Air Pressure (0.7-1.5 cubic meters/minute)

- High Air Pressure (7-30 cubic meters/minute)

| Model | Outside diameter (mm) | Working pressure (Mpa) | Air consumption (m³/min) | Hold diameter (mm) |

| CIR90 | 80 | 0.5-0.7 | 6 | 85-110 |

| CIR110 | 98 | 0.5-0.7 | 11 | 105-120 |

| CIR130 | 112 | 0.5-1.0 | 7-12 | 130-175 |

| CIR150 | 136 | 0.5-1.0 | 10-16 | 150-200 |

| Model | Outside diameter (mm) | Working pressure (Mpa) | Air consumption (m³/min) | Hold diameter (mm) |

| BR1 | 54 | 0.7-1.75 | 4.5-8.8 | 60-76 |

| BR2 | 63 | 0.7-2.0 | 5.5-8.8 | 70-95 |

| BR3 | 82 | 0.7-2.0 | 5.5-10.8 | 90-110 |

| BR4 | 95 | 0.7-17.2 | 1.9-10.8 | 105-127 |

| Model | Outside diameter (mm) | Working pressure (Mpa) | Air consumption (m³/min) | Hold diameter (mm) |

| DHD3.5/ DHD3.5A | 80 | 0.8-3.0 | 4.5-12.5 | 90-105 |

| DHD340/ DHD340A | 99 | 0.8-3.0 | 5.0-15 | 105-130 |

| DHD350/ DHD350A | 126 | 0.8-3.0 | 7.5-19.5 | 133-152 |

| DHD360/ DHD36A | 144 | 0.8-3.0 | 8.7-25.0 | 152-254 |

| DHD370 | 170 | 0.8-3.0 | 10-30 | 178-216 |

| DHD380/ DHD380A | 182 | 0.8-3.0 | 12-35 | 194-305 |

| DHD1120/DHD1120A | 275 | 1.4-3.0 | 36.6-56 | 305-400 |

| SD4 | 99 | 0.8-3.0 | 5.0-15 | 105-130 |

| SD5 | 126 | 0.8-3.0 | 7.5-19.5 | 133-152 |

| SD6 | 144 | 0.8-3.0 | 8.7-25.0 | 152-254 |

| SD8 | 182 | 0.8-3.0 | 12-35 | 194-305 |

| SD10 | 225 | 1.0-3.0 | 22-55 | 254-325 |

| SD12 | 275 | 1.4-3.0 | 36.6-56 | 305-400 |

| QL40 | 99 | 0.8-3.0 | 5.0-15 | 105-130 |

| QL50 | 126 | 0.8-3.0 | 7.5-19.5 | 133-152 |

| QL60 | 144 | 0.8-3.0 | 8.7-25.0 | 152-254 |

| QL80 | 182 | 0.8-3.0 | 12-35 | 194-305 |

| MISSION30/STR30 | 80 | 0.8-3.0 | 4.5-12.5 | 90-105 |

| MISSION40/ STR40 | 99 | 0.8-3.0 | 5.0-15 | 105-130 |

| MISSION50/ STR50 | 126 | 0.8-3.0 | 7.5-19.5 | 133-152 |

| MISSION60/ STR60 | 144 | 0.8-3.0 | 8.7-25.0 | 152-254 |

| MISSION80/ STR80 | 182 | 0.8-3.0 | 12-35 | 194-305 |

| N100/ STR100 | 225 | 1.0-3.0 | 22-55 | 254-325 |

| N120/ STR120 | 275 | 1.4-3.0 | 36.6-56 | 305-400 |

| N125 | 330 | 2.0-3.5 | 36.6-56 | 400-500 |

| N180 | 406 | 2.0-3.5 | 36.6-56 | 500-650 |

| N240 | 525 | 2.0-3.5 | 36.6-56 | 650-800 |

- Our DTH hammers incorporate advanced design elements that ensure smooth operation and improved stability, maximizing drilling effectiveness.

- Key components of our DTH hammers undergo specialized heat treatment to enhance durability and increase product reliability and longevity.

- By using our DTH hammers, you can achieve faster drilling speeds while reducing fuel consumption, ultimately saving costs for our valued customers.

- With its unique internal installation system, the DTH hammers ensure stable impact performance, delivering outstanding drilling efficiency and extended product lifespan.