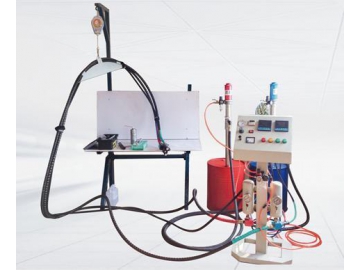

Rigid PU Foam Low Pressure Polyurethane Foam Machine

The rigid PU foam low pressure polyurethane foam machine is specially designed for the production of polyurethane products through mixing and pouring the polyurethane raw materials in an automatic process. The PU foaming machine is compatible with the foaming of 141B and complete water foaming systems.

The low pressure foaming machine mixes polyhydric alcohol and polyisocyanate materials through a motor that does not require a supercharging device. The motor has a relatively simple structure that operates with low cost.

This series of low pressure foaming machine is engineered for the processing of polyurethane foam plastics used for their good sealing performance, thermal insulation, and waterproofing properties. They are often used in refrigerators and cold storage units for insulation layers, heat accompanying pipelines, and building materials.

| Raw material viscosity (22℃) | Polyhydric alcohol: 3000MPas |

| Polyisocyanate: 1000MPas | |

| Injection flow rate | 2-6000g/s |

| Mix ratio | 100: 50~100:150 |

| Injection time | 0.5~99.99 S (Accurate to 0.01 S) |

| Material temperature control error | ±2℃ |

| Repeated injection accuracy | ±1% |

| Volume of tank | 30-500L |

| Compressed air consumption( dry and no oil) | P: 0.6-0.8Mpa |

| Q: 600NL/min | |

| Heating power | 2×3Kw |

| Input voltage | three-phase five-wire, 380V |

- Rigid Foam Low Pressure Polyurethane Foaming Machine

- Korea SPU high efficiency mixing head

- Feed pump

- Raw material tank

- Raw material filter

- Gelanrex metering pump

- Metering pump motor

- Water chiller

- Cleaning fluid tank

- Taiwan AirTAC cylinder

- Schneider AC contactor

- Fatek PLC controlling system

- Operation panel

1. High-precision metering pump can achieve a highly accurate materials ratio and measurement error will not exceed ±0.5%.

2. The frequency conversion motor is used to adjust the flow and pressure of raw materials, so the precision is high, and the materials ratio adjustment is quick and simple.

3. a high-performance mixing device delivers high accuracy raw materials feeding with synchronous and even mixing. A brand new sealing structure is adopted. The cooling water circulation contactors are reserved for ensure long-term continuous production to avoid clogging.

4. The storage tank is a three wall structure with a stainless steel liner and an external insulation layer, and the interlayer is used for heating. The storage tank is temperature adjustable, safe, and energy saving.

5. A materials testing system can be added. It can be switched at any time when testing the raw materials. It will not affect the normal production and eliminates waste caused by faulty finished products.

6. PLC and touch screen systems are used to control the pouring equipment, automatic cleaning and air flushing, for stable performance and easy operation. When the equipment is operating in an abnormal manner, it will automatically diagnose, alarm, and display abnormal factors. Safety and productivity are improved thanks to these systems.

7. PLC system can be used to load more settings, such as automatic feeding, automatic alarm when there is no raw material, clean the mixing head and so on.

If you do not find what you need on this table, please contact Lingxin directly and customize the polyurethane equipment that meets your actual needs.

LXPU-RY2-65 Rigid PU Foam Low Pressure Polyurethane Foam Machine| Foam type | Injection flow rate( mix ratio =1:1) | PLC system | Polyether polyol metering pump | Isocyanate metering pump | Total power | Size |

| Rigid foam | 3-65g/s | Fatek | JR-12 | JR-12 | 11KW | 3200x1650x2650mm |

LXPU-RY2-240 Rigid PU Foam Low Pressure Polyurethane Foam Machine

| Foam type | Injection flow rate( mix ratio =1:1) | PLC system | Polyether polyol metering pump | Isocyanate metering pump | Total power | Size |

| Rigid foam | 26-240g/s | Fatek | GPA-16 | GPA-16 | 20KW | 3200x1700x2650mm |

LXPU-H2-L150 Rigid PU Foam Low Pressure Polyurethane Foam Machine

| Foam type | Injection flow rate( mix ratio =1:1) | PLC system | Polyether polyol metering pump | Isocyanate metering pump | Total power | Size |

| Rigid foam | 80-800g/s | Fatek | GPA-63 | GPA-63 | 28KW | 3400x1800x2650mm |

LXPU-RY2-3300 Rigid PU Foam Low Pressure Polyurethane Foam Machine

| Foam type | Injection flow rate( mix ratio =1:1) | PLC system | Polyether polyol metering pump | Isocyanate metering pump | Total power | Size |

| Rigid foam | 330-3300g/s | Fatek | TG GP23-65 | TG GP23-65 | 50KW | 3500x1800x2650mm |

Index

PU plant, PU processing equipment, mix head, metering pump, PU foam production line, PU equipment