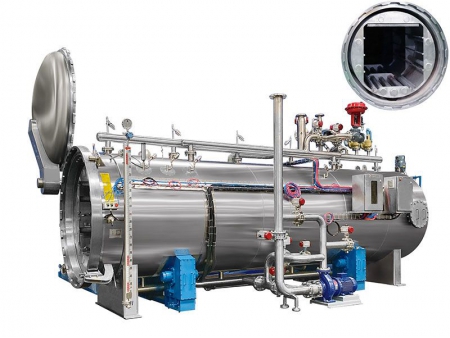

Spray Type Deaerator

The spray type deaerator goes by many names. Single-vessel deaerator and one-piece deaerator are just a couple. As a state-of-the-art device, the spray-type deaerator overcomes several setbacks in boiler feedwater deaeration, such as stress concentration, metal corrosion damage, insecure operation, and over-sized opening.

Compared to deaeration methods, our single-vessel deaeration unit allows 20% to 50% less metal loss. It has a light weight and is available at a competitive price. Its unique spray nozzle enables the boil feed water to be preheated before shooting out into the steam atmosphere. After preheating, the atomized water is heated by the steam thoroughly to ensure optimum oxygen removal with the oxygen content reduced to less than 5 mg/L.

Take a look around the site, and customers will quickly notice a wide range of specifications, each being designed to suit a specific deaeration removal task. Our deaerator can be connected as either an upstream or downstream component to the 1300MW genset or industrial-grade boiler, stripping out 20 to 6000 tons of gases per hour. Please contact us for more information on our mechanical deaeration devices.

Features

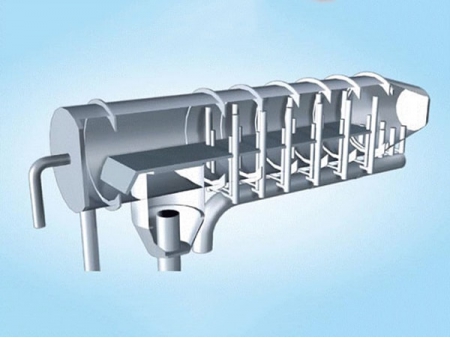

1. STORK patented spray nozzle does not contain rotating parts. It is maintenance free, delivering a service life of up to 30 years.

2. For genset at power above 200MW, it is more wise to invest in our spray type deaerator than the tray-type unit since the overall cost of the former is much less than the latter with the same deaeration performance.

3. The elimination of deaeration head in the spray type deaerator avoids too much load impacting directly on the upper part of the vessel. Thus, the stress acting upon the vessel is greatly reduced, which in turn prevents the risk of vessel crack or rupture thereby extending its service life. Even more beneficial, a non-dome deaeration design provides an overall height reduction of 3~4m. This translates into considerable factor construction cost savings.

4. Deaerator maintenance is easily done with the aid of a platform which needs to be arranged along the length of the vessel.

5. Quiet operation produces low noise. The decibel level created by our spray type deaerator under full load is less than 65dB.

If you have a need for our spray-type, please send us necessary information as listed below.

1. Capacity(t/h)

2. Vessel volume(m3)

3. Operating pressure (MPa)

4. Operating temperature (℃ )

5. Installation height and conditions

6. Number of structural steel stands