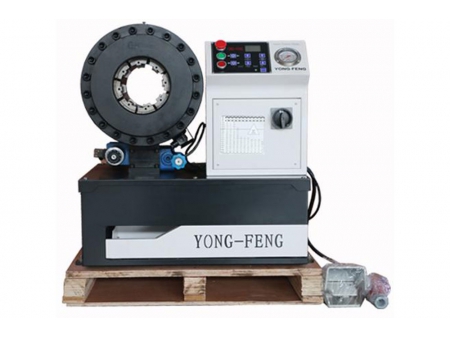

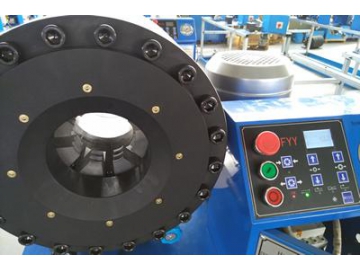

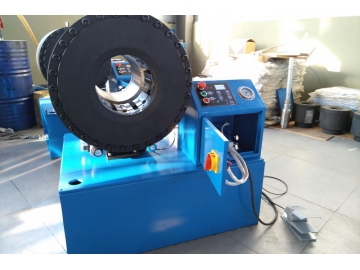

Crimping Machine

Request a Quote

- Crimping Machine

- The roofing roll forming machine makes roof panels. Then the crimping machines make roof panels curved.

The crimping machine is often used together with other metal forming equipment to assist in sheet metal forming and fabrication. It is especially popular for working with our roll forming machines to help fabrication of roofing sheets.

Technical Data of the Crimping Machine| Raw material | Corrugated steel sheet (235-345Mpa) |

| Material of roller | 45# steel being quenched |

| Material of crimping device | Cr12 mould steel with quenching treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Crimping speed | about 10times /minute |

| Power Requirement | Main motor power: 2.2Kw (Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Diameter of shaft for rollers | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of feeding rollers | about 3 stations for main rollers |

| Weight of machine | About 3000KGS |

| Size of machine | about 1600mm×1600mm×1750mm |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos