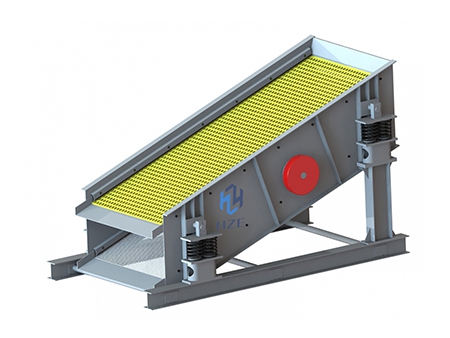

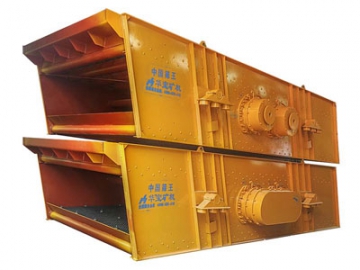

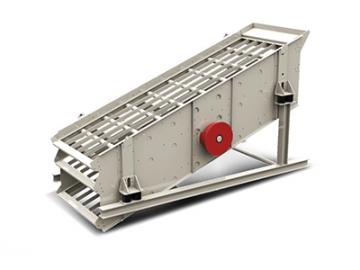

Circular Vibrating Screen

Spiral Classifier

Working Principle

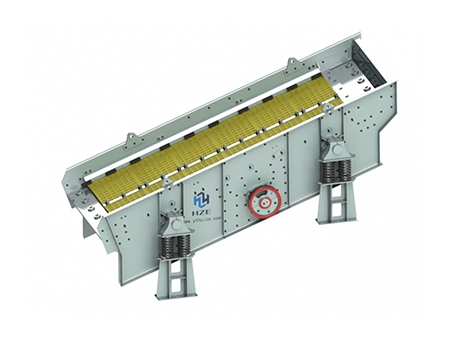

The circular vibrating screen is comprised of screen box, screen mesh, vibrator, damping spring and so on. The vibrator is installed on the side plate of the screen box and is driven to rotate by the motor via the V belt. The vibrator generates centrifugal force that causes the vibration of the screen box in an approximately circular path. Materials of size smaller than the classifier aperture will fall to the classifier below; while materials of size larger than the apeture will be discharged from the outlet, and then the screening is finished.

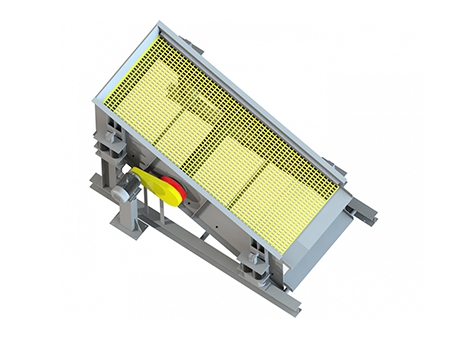

- Equipped with eccentric shaft and eccentric block, the virbator operates stably and efficiently in screening.

- The vibrating screen gains its name from its circle-like shape; it is a multi-layered vibrating screen of high efficiency.

- Vibration can remove the materials stuck in the mesh.

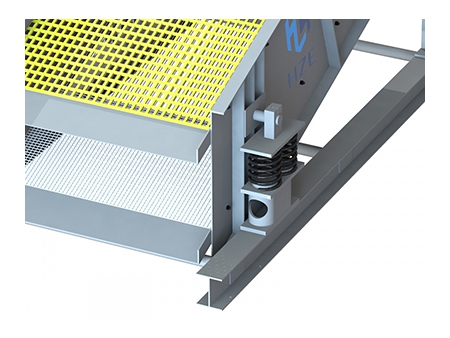

- Adopts low-stress damping spring to lower the noise.

- Extra large clearance bearing keeps the temperature low and prolongs the service life.

- Adopts ring-grooved rivet and plate-type screen box to solidify the frame structuer.

- The screen mesh can be made from TPU, stainless steel, rubber or other abrasion-proof materials.

Circular vibrating screen is one of the most frequently used mining equipment, extensively applied in mineral processing, construction materials, silicate and chemical industries. In small, medium and large scale mineral processing plants, the circular vibrating screen is used to sort out metal ores such as gold, silver, bronze, lead, zinc, nickel. manganese, iron and molybdenum, also stones such as rock, granite, limestone, barite, quartz, graphite, feldspar and fluorite.

The circular vibrating screen can also used for dewatering, desliming, medium drainage and so on.

| Model | Screen Deck | Feeding Size (mm) | Capacity (t/h) | Electric Motor | |||

| Area (m2) | Angle (°) | Aperture (mm) | Model | Power (kW) | |||

YA1236 | 4.3 | 20 | 6~50 | ≤200 | 75~245 | Y160M-4 | 11 |

YA1530 | 4.5 | 80~240 | Y160M-4 | 11 | |||

YA1536 | 5.4 | 95~310 | Y160M-4 | 11 | |||

YA1536 | ≤400 | 100~350 | Y160L-4 | 11 | |||

YA1542 | 6.3 | 6~50 | ≤200 | 110~385 | Y160M-4 | 11 | |

YA1548 | 7.2 | 6~50 | 120~420 | Y160L-4 | 15 | ||

YAH1548 | 30~150 | ≤400 | 200~780 | Y160L-4 | 15 | ||

| Model | Screen Deck | Feeding Size (mm) | Capacity(t/h) | Electric Motor | |||

| Area (m2) | Angle (°) | Aperture(mm) | Model | Power (kW) | |||

YA1836 | 6.5 | 20 | 30~150 | ≤200 | 115~370 | Y160M-4 | 11 |

YAH1836 | 6.5 | 30~150 | ≤400 | 220~800 | Y160M-4 | 11 | |

YA1842 | 7.6 | 6~50 | ≤200 | 135~430 | Y160L-4 | 15 | |

2YA1842 | 7.6 | 6~150 | 135~430 | Y160L-4 | 15 | ||

YAH1842 | 7.6 | 30~150 | ≤400 | 340~900 | Y160L-4 | 15 | |

YA1848 | 8.6 | 6~50 | ≤200 | 150~490 | Y160L-4 | 15 | |

2YA1848 | 8.6 | 150~490 | Y160L-4 | 15 | |||

YA2148 | 10 | 6~50 | ≤200 | 175~570 | Y180M-4 | 18.5 | |

2YA2148 | 10 | 6~50 | ≤200 | 175~570 | Y180L-4 | 22 | |

| Model | Screen Deck | Feeding Size (mm) | Capacity(t/h) | Electric Motor | |||

| Area (m2) | Angle (°) | Aperture (mm) | Model | Power (kW) | |||

YA2160 | 12.6 | 20 | 6~80 | ≤200 | 230~800 | Y180M-4 | 18.5 |

2YA2160 | 12.6 | 6~50 | ≤200 | 220~715 | Y180L-4 | 22 | |

YA2448 | 11.5 | 6~50 | ≤200 | 200~650 | Y180 M -4 | 18.5 | |

YA2460 | 14.4 | 6~50 | ≤200 | 260~780 | Y200L-4 | 30 | |

2YA2460 | 14.4 | 6~50 | ≤200 | 260~780 | Y200L-4 | 30 | |