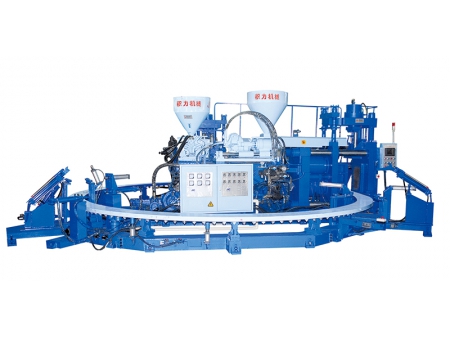

One Color PVC Slipper Injection Molding Machine

Request a Quote

View All: http://footwear-makingmachine.com/2-3-one-color-pvc-slipper-injection-molding-machine.html

Rotary air blowing injection molding machine for producing plastic slippers and sandals

- The built-in screw design occupies less space;

- The slipper making machine is used to produce V-shaped products;

- It features strong clamping force to ensure high product quality;

Raw material: PVC

Applications:

The slipper injection molding machine is used to produce one-color V-shaped PVC products in an air-blowing manner, such as, soles, slippers, sandals and jelly shoes.

Technical Specifications

| Item | Unit | Specifications | |||

| Model | | | | | |

| Raw material | PVC | PVC | PVC | PVC | |

| Max. number of station | 24 | 24 | 24 | 24 | |

| Clamping force | T | 60 | 60 | 80 | 80 |

| Mold height | mm | 80-240 | 50-300 | 50-300 | 50-300 |

| Screw diameter | mm | Ø70 | Ø70 | Ø70 | Ø70 |

| Screw rotational speed | RPM | 0-150 | 0-150 | 0-150 | 0-150 |

| Max. injection volume | cm³/cc | 770 | 770 | 770 | 770 |

| Rated injection pressure | kg/cm² | 0-120 | 0-120 | 0-120 | 0-120 |

| Motor power | kW | 18.5 | 18.5 | 18.5 | 18.5 |

| Power of heating | kW | 13 | 13 | 13 | 13 |

| Temperature setting | stage | 4 | 4 | 4 | 4 |

| Max. mold size | mm | 460*220*240 | 460*220*300 | 460*220*300 | 460*220*300 |

| Machine dimensions | mm | 4460*4050*2300 | 4460*4050*2300 | 4460*4050*2500 | 4460*4050*2500 |

| Gross weight | kg | 6000 | 6500 | 6800 | 7200 |

Features

- The air blowing injection molding machine is designed to produce one-color PVC soles, slippers, sandals and jelly shoes;

- A PLC system provides the advantages that improve the efficiency, safety and reliability of industrial process;

- The control panel function design is simple to learn and operate;

- The slipper making machine features a large injection volume and a strong clamping force, which ensures high-quality soles;

- A feeding nozzle switch saves working time and increases productivity;

- The hydraulic system with a dual-ratio control valve enables flexible adjustment of the injection velocity, pressure and the feeding volume;

- Products are made based on specific needs.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos