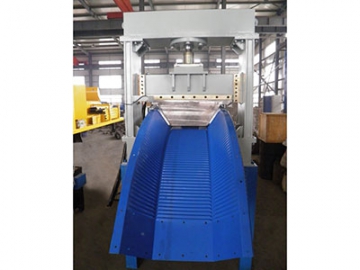

Curved Sheet Screw Jointed Equipment

Features

1.The curved sheet screw jointed equipment is capable of making panels in different sizes based on the requirement of the project.

2. Once finished in the workshop, the product is allowed to be delivered to the construction site directly.

3. The panels jointed by our machine are very convenient for dismounting.

4. The panel makes the building with 100% available space, available in mounting with lighting, pipeline, ventilated devices, warming and cooling systems.

5. The building formed by the panels is removable.

Working Process

1.Building arches

2.Raising arches

3.Choosing the fit arches together

4.Adding the end walls

5.Establishing the foundation of the buildings

6.Transporting the finished curved sheets to construction site

7.Jointing the curved sheets together

8.Hoisting and fastening the jointed curved sheets

9.Reinforcing the curved sheets with the foundation together

10.Building the gables at two sides.

11.Constructing the doors and windows of the buildings

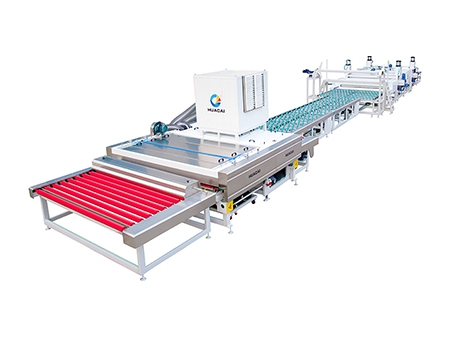

1. Dimension: 35000mm×1500mm×1500mm

2. Weight: Around 20T

3. Shearing material: 12CrMoV

4. Shearing type: Mechanical

5. Total motor power: 25KW

6. Main motor: 7.5KW

7. Decoiler motor: 3.0KW

8. Leveling machine motor: 4.0KW

9. Shearing machine motor: 3.0KW

10. Hydraulic station power: 7.5KW

11. Roller material: 45# high-quality steel (Standard), quenched HRC 55~65, hard chrome plating

12. Shaft material: 45# high-quality steel, galvanized

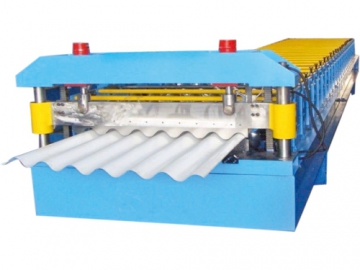

13. Stands of forming: 10

14. Feeding width: 1000mm

15. Effective width: 680mm

16. Using rate: 68%

17. Rolling thickness: 1.0-1.2mm

18. Suitable Span: 4m-24m

19. Decoiler: Load bearing: 8t

Equipment Configuration

8t Automatic feeding device (1 piece), Leveling machine (1 piece), Support platform (1 piece), Edge-punching (1set of mold), Ends-punching (1set of mold ), Shearing machine(1 piece), Forming machine (1 piece), Bending machine 1 piece (1set of mold), Hydraulic system, Electrical control system, Support for finished product, etc.

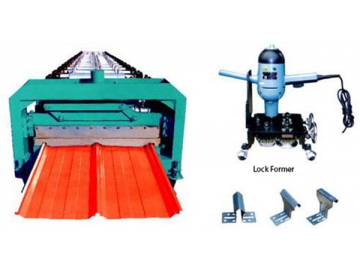

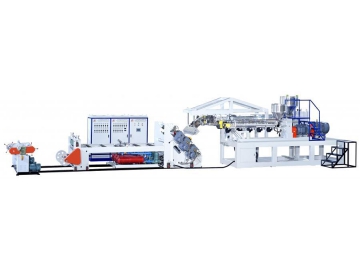

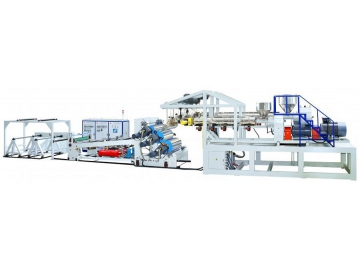

Technological Process

Loading (load & expand galvanized coil on decoiler) → Feeding & Leveling (prepare flat galvanized sheet for punching) → Edge-punching & Ends-punching on flat galvanized sheet → Shearing punched sheet → Roll forming sheared sheet → Bending Roll formed sheet

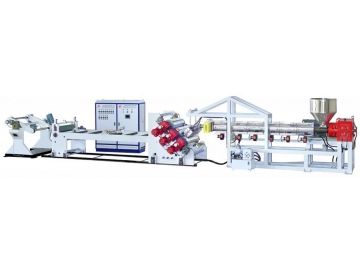

| Equipment & Accessory | ||

| No. | Qty. | |

| 1 | Decoiler | 1 piece |

| 2 | Leveling machine | 1 piece |

| 3 | Shearing machine | 1 piece |

| 4 | Roll forming machine | 1 piece |

| 5 | Hydraulic punching machine | 1 piece |

| 6 | Molds | 3 sets |

| 7 | Support platform | 1 piece |

| 8 | Chain | 3 pieces |

| 9 | Half section | 3 pieces |

| 10 | Bearing | 4 pieces |