TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

Our CNC plate drilling machine is applicable for drilling on the junction and bed plates in steel structure, steel tower, bridge, and machinery industries.

Features

1. Our CNC drilling machine is used for drilling holes on metal plates used in steel structures, electric power supply towers, and petrochemical equipment. With a gantry style structure, the X axis, Y axis and Z axis are all driven along the linear guide by a servo motor with the use of a precise ball screw.

This steel plate driller can accomplish automatic, precise and fast positioning and processing. It improves upon the precision and speed of the drilling. At the same time, this machine also easily avoids needing repairs or replaced because of manual positions or drilling errors.

2. This CNC plate drilling machine uses a host computer and PLC control system. The computer is installed with automatic programming software and monitoring software, which can directly convert the AUTOCAD graph file to a processing program. The manual programming is also fast and easy, even for someone inexperienced.

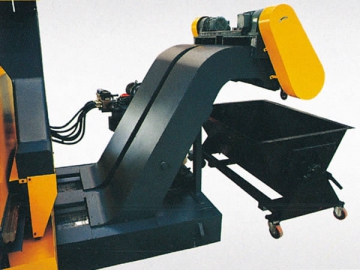

3. The hydraulic clamps on our mobile CNC drill press can clamp and loosen the work piece, which results in reliable, stable and fast clamping. The automatic chip removal device and circulation cooling system both reduce unproductive time and labor intensity. Operating staff only needs to load and unload the work pieces and change drills.

4. According to different diameters of holes, the advanced CNC drilling spindle of our CNC processing equipment can automatically adjust the feeding and rotation speeds to their optimum performances via computer control. It can also be manually adjusted based on different conditions.

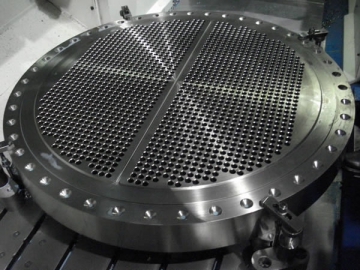

Our CNC plate drilling machine is capable of processing through holes, blind holes, and counter bores. Each principle axis has a #4 Morse taper at the lower end. Our CNC machinery for steel plates is equipped with spanners that are used for disassembling the drills, which avoids knocking and guarantees the machine’s precision and lifespan. We also supply #3 and #2 Morse reducing sleeves, and high speed steel twist drills with diameters smaller than 50 mm.

5. Its design is meant to conform to the features and precision requirements of work pieces. Our CNC drilling machine has a compact and flexible structure, which can meet processing requirements easier. It can quickly and accurately drill the holes within a circular distribution or on a straight line.

Parameters| Model | ||||||

| Max size of workpiece (mm) | one piece | 2,000×1,000 | 2,000×1,200 | 2,000×1,600 | 3,000×1,600 | |

| two pieces | 1,000×1,000 | 1,000×1,200 | 1,600×1,000 | 1,600×1,500 | ||

| four pieces | 1,000×500 | 1,000×600 | 800×500 | 1,500×800 | ||

| Max. thickness of workpiece | 100mm; thinner plates can have overlap processing | |||||

| Morse taper of spindle | #4 | |||||

| Max. drilling diameter | Φ50mm | |||||

| Drilling spindle | Rotation speed(rpm) | From 120 to 560 (Stepless speed adjustment) | ||||

| Max. stroke of feeding (mm) | 350 | |||||

| Motor power(kw) | 5.5 | |||||

| Quantity of clamps | 12 | |||||

| Clamping force(kn/each) | 7.5 | |||||

| Motor power(kw) | Servo motors | X axis | 1.3 | |||

| Y axis | 1.3 | |||||

| Z axis | 0.85 | |||||

| Motor for hydraulic system | 1.5 | |||||

| Drive motor for chip collector | 0.75 | |||||

| Motor for cooling pump | 0.25 | |||||

| Net weight(kg) | 5,200 | 6,200 | 7,200 | 8,200 | ||

| Dimension(L×W×H)(mm) | 3,000×1,950×2,790 | 3,000×2,150×2,790 | 3,000×2,420×2,790 | 4,000×2,420×2,790 | ||