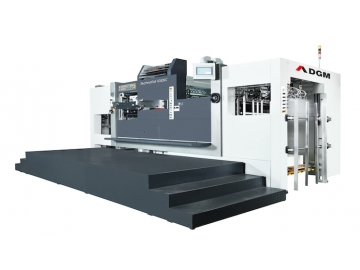

Description

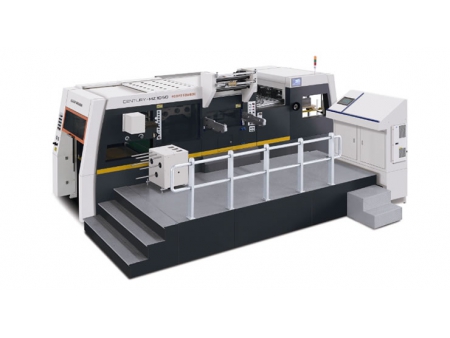

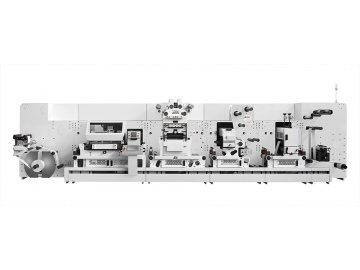

With a transverse foil pull system, the 1050-SC type hot foil stamping cutting line is fit for the large format die-cutting and the stamping of single-color pattern of papers, carton boards and corrugated boards with different specifications. Its maximum stamping speed reaches up to 6000 sheets every hour.

This die cutting and foil stamping press uses quick locking and central positioning system to meet the requirements of high-precision waste discharging. At the same time, this machine also supports automatic cooling and die-cutting after the hot stamping process is completed.

This hot foil stamper is of excellent resistance to elevated temperature, capable of operating hot stamping under a high temperature of 200℃. It also has the ability of cooling the high-temperature boards.

Processed materials - Paper

- Carbon board

- Corrugated board

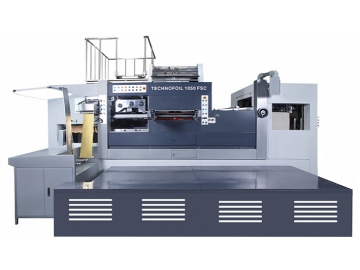

Parameters Processed materials | Paper | 80 g/m² |

| Maximum carbon board | 2000 g/m² |

| Maximum corrugated board | 4 mm |

Capability | Min. Sheet size | 350 x 400 mm |

| Max. Sheet size | 740 x 1050 mm |

| Speed | 7500 sheets/h |

| Max. Foil stamping speed | 6000 sheets/h |

| Die-cutting force | 300 Ton |

Converting | Max. stamping size | 580 x 1020 mm |

| Max. Die-cutting size | 730 x 1040 mm |

Heating system | Heating zones | 12 units |

| Max. temperature | 200 ºC |

Foil equipment | Foil length | 120 to 1200 m |

| Foil width | 50 to 630 mm |

| Web advance shafts | 2 |

Pile height | Feeder | 1650 mm |

| Max. Feeder with non-stop | 1270 mm |

| Delivery | 1300 mm |

Dimensions and Weight | L x W x H | 7.08 x4.28x3.26m |

| Weight | 17.5 Ton |

Installation | Power | 35 kW |

| Compressed air | 6 bar |

| Air compressor capacity | 30 m³/h |

| Air tank capacity | 155 L |

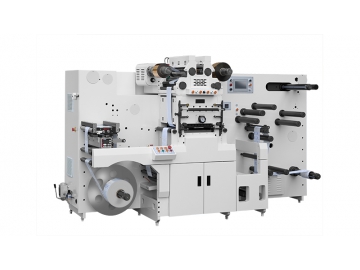

Die Cutting and Foil Stamping Presses Components -

Feeder section

- Continuous feeder without interruptions, feeding through pallets or carts

- Material loading by pallets or carts

- Designed with 4 lifting suckers and 4 forwarding suckers, ensuring smooth feeding of cardboard and corrugated board with different thicknesses in an efficient, reliable, and precise manner

- Double sheet detector

-

Register table

- Quick changeovers, easy adjustment for sheet size

- The sheet alignment on the side can be easily made on the register table with guide rails.

- 4 front register lays, independently adjustable

-

Press section

- The die cutter chase is designed with a central positioning system for fast positioning of the die.

- Cutting die with 5 mm thickness

- The pressure can be easily adjusted through the touch screen. Adopting over-pressure protection avoids any damage in the press.

- Available with manual or automatic lubrication system.

- 7 light weight gripper bars

- Changer-over bracket for cutting chase and honeycomb chase.

- Pneumatic lock and release system for cutting chase and honeycomb chase.

-

Foil stamping system

- The heating system features 12 temperature zones with individual temperature control.

- Foil break detector

- Foil fasten device

- Foil unwind device

- Honeycomb chase

-

Stripping section

- Optimized cam movement curve guarantees stripping stability and accuracy.

- Quick-locking and central positioning system assures the waste is cleared in a precise and quick manner.

-

Delivery section

- Automatic delivery with non-stop curtain

-

Transverse foil stamping system

- 2 foil rolls in a high precision transversal foil feeding system.