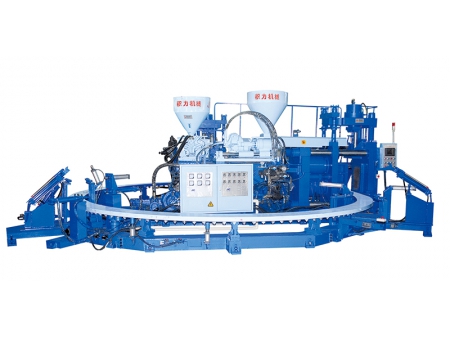

Two Color TPE Shoe Cover Injection Molding Machine

Request a Quote

View All: http://footwear-makingmachine.com/2-6-two-color-tpe-shoe-cover-injection-molding-machine.html

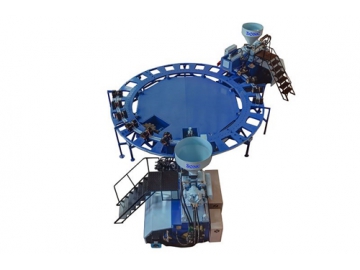

Rotary injection molding machine for producing shoe covers and galoshes

- The TPE injection molding machine is used to produce rain boots and shoe covers in one color and two colors;

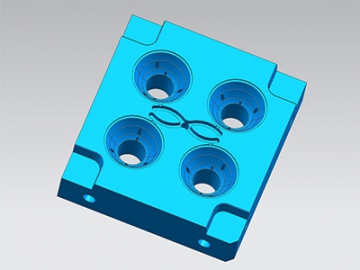

- The mold closing process is stable and reliable, and the clamping force is balanced to ensure high product quality;

- The structure of molds is simple for easy replacement and maintenance.

Raw material: TPE

Applications:

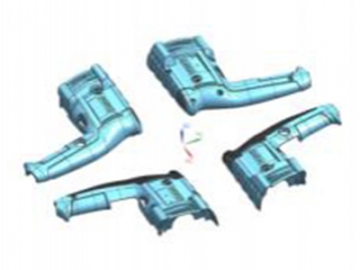

one-color and two-color shoe covers

Technical Specifications

| Item | Unit | Specifications | |

| Model | | | |

| Raw material | TPE | TPE | |

| Number of stations | 12 (14 or 16) | 12 (14 or 16) | |

| Max. injection volume | cm³/cc | 770, 1270 | 500, 770 |

| Rated injection pressure | kg/cm² | 0-120 | 0-120 |

| Power of electric heating | kW | 13 15 | 9 13 |

| Temperature setting | stage | 5 | 5 |

| Screw rotational speed | RPM | 0-150 | 0-150 |

| Screw diameter | mm | Ø70,Ø90 | Ø55,Ø70 |

| Motor power | kW | 15,22 | 15,18.5 |

| Clamping force | T | 250 | 250 |

| Max. mold size | mm | 680*360*200 | 520*360*200 |

| Machine dimensions | mm | 5500*5050*2450 | 5710*4720*2170 |

| Gross weight | kg | 18500 | 16800 |

Features

- The injection molding machine is widely used to make TPE shoe cover in one color and two colors;

- The TPE injection machine is equipped with an industrial interface, a PLC and a touchscreen;

- The dual-ratio hydraulic control valve precisely controls the injection pressure and the rate of flow to produce high-quality shoe covers;

- The digital measurement system ensures stable production performance;

- The touch panel is designed to be simple and easy to operate;

- Our fabulous injection machine is equipped with a robotic arm to realize fully automatic production;

- The servomotor system reaches the same performance with less energy consumption compared to traditional motors.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos