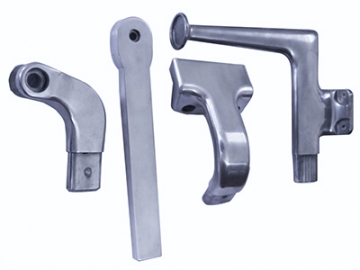

Aluminum Die Castings

Aluminum Die Casting Customization Solution

We have premium aluminum die castings, aluminum die cast car parts, aluminum die cast door fittings, aluminum die cast window accessories and aluminum die cast lamp parts, which have complex shapes and thinner wall. The aluminum die castings have excellent performance in high temperature condition and feature good corrosion resistance, competent mechanical performance, high thermal conductivity and high electrical conductivity.

Production Capacity

1. We can handle a large number of orders and produce quantities of aluminum die castings by utilizing our automatic equipment. Our weekly production can reach 100,000 pieces.

2. Our small batch of orders can be manually handled. The annual production is at least 500 pieces.

3. Our product weight of ranges from 0.02kg to 10kg.

4. Our aluminum die casting parts support single-cavity and multi-cavity.

5. Most of the aluminum die casting materials, such as ADC10,ADC12,A380, A383,B390 (YL117),YL112,YL104, are all available.

6. We have 10 production lines of die casting and gravity casting, and each of them is equipped with a furnace. Therefore, we can produce various kinds of aluminum die castings everyday.

7. For effective production of aluminum die cast parts, we have 7 cold chamber die casting machines, of which the tonnage ranges from 125tons to 800tons. We also have 3 gravity casting machines.

On-site Molding Service

We provide independent die casting mold design and production in addition to the aluminum die castings. Superior to other die casting manufacturers only having maintenance service, we are a full-service manufacturer providing on-site molding service in accordance with customers’ requirements. The production starts when the molds are simply transferred to the casting area.

We can obtain the related data from the latest 3D solid model, a simple draft or a sample and produce mold sample and molds. Additionally, the most advanced multi-axis CNC machine will be adopted to achieve the optimum precision and accuracy.

Advanced Finishing Technology

We are equipped with complete and independent in-house processing equipment, such as CNC Milling machine, which can provide precision processing for the pressure cast products. Our surface finishing technology includes sandblasting, vibrating polishing, chrome plating, powder coating, paint spraying, anodic oxidation, etc. We are delighted to provide one-stop service of aluminum die castings.