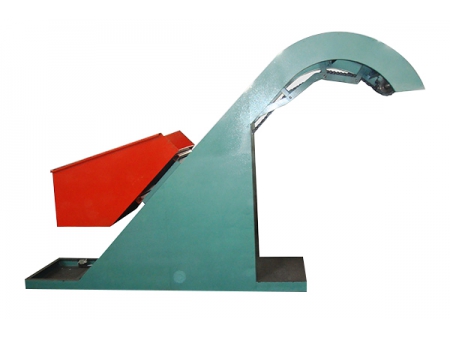

Bucket Elevator

As materials get in the hopper via a vibrating table, they are quickly sent inside the bucket elevator with a series of buckets running continuously up along the leg.

Excellent qualities including large handling capacity, great lifting height, stable operation, and long service life are further enhanced by a rugged design. We currently offer bucket conveyors in three types, plate link chain, belt, and plate link chain.

The TDTG series bucket elevator in the extruded food production line can handle a variety of powders, pellets and small lumps across industries, including the animal feeds, grains, cooking oil, foods, building materials, chemicals, medicines, and loading docks.

Features of Bucket Elevator

1. A small footprint means the elevator takes up little floor space.

2. Head

Head pulleys are rubber coated for increased friction and transmission efficiency. Head sections are properly designed to extend the length of the discharge chute, eliminating the need for throat plate or buffer chamber. The result is minimized material falling down the up or down leg (which is known as backlegging). Replaceable head linings make for higher wear resistance.

3. Trunk

Trunk sections are rigid, fully enclosed pipes with their edges closed by using lockformer machines. A pressure equalizing pipe is added to the trunk section for balance of pressure between two legs. Tool-free inspection door allows easy access to the internal trunk. Explosion vents effectively relieve the entire system of pressure.

4. Boot

Advanced shaft seal keeps internal dust from leaking out. Split pillow block bearing housing ensures maximum reliability. Baffle plate for flow control comes with two layers of seal which prevent material leakage.

5. Backstop

The use of a backstop prevents reverse rotation of drive pulley in case of a motor shut down. This also avoids material clogging up the elevator.

6. Speed Sensor, Belt Tracking Devices

Speed sensing and belt tracking makes sure the belt is up and running continuously.

| Model | ||||||||

| Capacity | Pellets | 5 | 10 | 15 | 25 | 35 | 45 | 65 |

| Powder | 3 | 5 | 10 | 20 | 25 | 25 | 35 | |