Concrete Batching Plant

Instruction

Product Introduction

1. HZS concrete batching plant, also called full automatic concrete mixer, is a kind of compulsory and efficient mixing equipment.

2. This complete mixing plant is composed of mixer, weighing system, batchers and belt conveyor or hopper feeding system matched to them, cement silos and screw conveyor matched to them, control system which is divided into centralized control system and standard system, control room, etc.

3. JS series double shaft concrete mixer is usually used as the main mixer in the batching plant. We can offer reference configuration for the batchers and cement silos. Also, the configuration can be customized based on customer's requirements.

Features and Advantages

1. This concrete batching plant comes with newly designed automatic systems such as electric weighing, computer control, digital display, etc. The electric weighing system is designed with buffer device and self-compensating function, which ensures weighing accuracy up to 99%.

2. Aggregate batcher adopts hopper or wide herringbone belt to feed materials and boasts a user friendly maintenance walkway, so it is greatly popular in most construction units for producing high quality concrete. Additionally, the aggregate batching system features compact structure, reliable performance, and convenient maintenance.

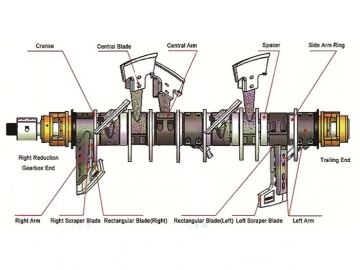

3. Combining the technology of Zhuhai SICOMA mixer and ours, we make improvements on inherent performance of the mixer of our concrete batching plant. The mixer is optimally designed with centralized lubricating system and motor-driven or air operated discharging gate which can ensure discharging in sections to avoid blocking. In addition, the discharging gate can be operated both automatically and manually, which can handle emergency such as power failure.

4. The operating desk with manual buttons, various display instruments, industrial control computer, etc. is used to operate the system. The display instrument and manual button can indicate current working condition of the system and the manual button can be used to achieve manual operation to this system. Alternative strong electric cabinet or operating desk is designed with air switch, contactor, intermediate relay and some protective devices on the rear. See details of specific functions and connection method in electric installation drawing.

5. According to the difference of production mark, the process and time series of feeding is adjustable to meet two-step material feeding process and water feeding process. As for the former process, sand, cement, additive and fly ash are firstly fed into the mixer, and then stone will be fed after a certain time of mixing. As for the two-step water feeding process, the first step is to feed 80% water into the mixer, and the remained part will be fed after a certain time of mixing. The process can be set by software, thus ensuring easy adjustment.

Applications

1. Our efficient concrete batching plant can be used to mix plastic or harsh concrete.

2. It is also the ideal choice for large and medium scale construction, road and bridge construction project, as well as concrete factories for prefabrication.

| Model | |||||||

| Max. production rate | 180m3 /h | 120m3 /h | 90m3 /h | 60 m3 /h | 35 m3 /h | 25 m3 /h | |

| Mixer model | JS3000 | JS2000 | JS1500 | JS1000 | JS750 | JS500 | |

| Aggregate category | 4 | 4 | 4 | 4 | 3 | 3 | |

| Max. diameter of aggregate(pebble / gravel) | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | 80/60mm | |

| Discharge height | 4200mm | 3800mm | 3800mm | 3800mm | 3800mm | 3800mm | |

| Aggregate | Weighing range | 0-3000kg × 4 | 0-1250kg × 4 | 0-1000kg × 4 | 0-2500kg | 0-1800kg | 0-1200kg |

| Weighing accuracy | ± 2% | ± 2% | ± 2% | ± 2% | ± 2% | ± 2% | |

| Cement | Weighing range | 0-1500kg | 0-1200kg | 0-900kg | 0-600kg | 0-450kg | 0-300kg |

| Weighing accuracy | ± 1% | ± 1% | ± 1% | ± 1% | ± 1% | ± 1% | |

| Water | Weighing range | 0-800kg | 0-600kg | 0-450kg | 0-300kg | 0-200kg | 0-150kg |

| Weighing accuracy | ± 1% | ± 1% | ± 1% | ± 1% | ± 1% | ± 1% | |

| Additive | Weighing range | 0-60kg | 0-60kg | 0-40kg | 0-40kg | 0-30kg | 0-30kg |

| Weighing accuracy | ± 1% | ± 1% | ± 1% | ± 1% | ± 1% | ± 1% | |

Models

- It can be used with cement silo or other equipment. On average, it weighs 2 to 4 kinds of aggregate. Users can use this concrete batching equipment in conjunction with blenders and other metering equipment to form an automatic or semi-automatic mixing station.

- This helical screw of this auger conveyor features small diameter, high speed rotating speed, high accuracy, large conveying capacity, and perfect working condition. The drive unit is designed with gear reducer which comes with large torque, low noise generation, no greasing, long service life, etc.

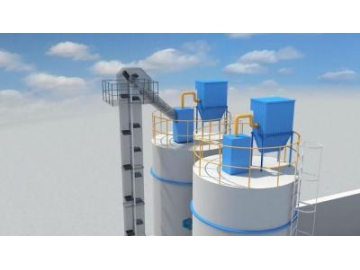

- The cement silo comes with cylindrical structure and there are four tube legs under its bottom for supporting the silo. The entire silo is welded by steel and is equipped with ladder, guardrail, feeding pipe, dust collector, pressure relief valve, level gage, arch breaker (blower), discharge valve, etc.

- When the system is in automatic working, the indicator lights of all working buttons on the operating desk will be on. Thus, it is clear to know the working condition. When it is in full automatic operation, the start button is just needed to be pressed only once ...

- Chassis Model: Mercedes /HOWO/Shangxi automobile/DONGFENG/Customized

Overall Dimensions: 9135*2490*3810

Total Weight: 25000